RESHAPING THE GOVERNMENT-INDUSTRIAL RELATIONSHIP FOR LOGISTICS SUPPORT AND SUSTAINMENT: RANDY FOWLER ON MEETING THE CHALLENGES

Sldinfo sat down with Randy Fowler, Deputy Assistant Secretary of Defense for Materiel Readiness, and his staff in mid December 2009 to discuss their perspectives on the way ahead in dealing with sustainment., as a well as report published last November on this very issue: the interview follows a brief presentation of the latter.

***

AN OVERVIEW OF DOD’S WEAPON SYSTEMS ACQUISITION REFORM PRODUCT SUPPORT REPORT

Full Focus on Acquisition Reform

With the arrival of the new Administration, there has been a core emphasis on acquisition reform. In fact, one of the earliest accomplishments in this Administration was the Weapon Systems Acquisition Reform Act, signed into law on May 22, 2009. But it appears that in this cycle of reform the Administration will not be content with just addressing the front-end costs of buying new weapons systems.

Instead, there is a growing recognition by the current leadership of the need to simultaneously consider the cost of logistics support during design and development and to shape ways to lower total costs across the life cycle, not just acquisition costs. A consensus view is emerging that to truly reform acquisition, you have to consider the full life cycle and optimize across the industrial base, including the spectrum of capabilities in the organic base and in the commercial sector. It’s about balanced and considered industrial base strategies to deliver the best value, the most cost effective support, to the warfighter. A recent report from OSD addresses the future of the business model underlying sustainment and suggests ways ahead in shaping the public-private sector relationship. The report (DOD Weapon System Acquisition Reform Product Support Assessment) was produced by a government-industry team headed by Randy Fowler, Deputy Assistant Secretary of Defense for Materiel Readiness. A 65-member team worked for a year and has produced a final report published in November 2009, which identifies a number of product support and acquisition reforms, which would make sustainment approaches more effective.

The Undersecretary of Defense for Acquisition, Technology and Logistics, Ashton Carter, has underscored his support for the effort. “I appreciate the team’s work to arrive at these findings and to publish this comprehensive report. Please be assured you will have my support during implementation of the eight recommendations. I look forward to working with the DoD Components and Agencies, Congress, Industry, and the Warfighter as we implement successful change in weapon system product support and acquisition reform. Your cooperation is paramount. Let’s drive this effort home!”

The Undersecretary of Defense for Acquisition, Technology and Logistics, Ashton Carter, has underscored his support for the effort. “I appreciate the team’s work to arrive at these findings and to publish this comprehensive report. Please be assured you will have my support during implementation of the eight recommendations. I look forward to working with the DoD Components and Agencies, Congress, Industry, and the Warfighter as we implement successful change in weapon system product support and acquisition reform. Your cooperation is paramount. Let’s drive this effort home!”

The goal of the effort according to the report is “to achieve aligned and synchronized operational, acquisition, and sustainment communities working together to deliver required and affordable Warfighter outcomes” (page 7).

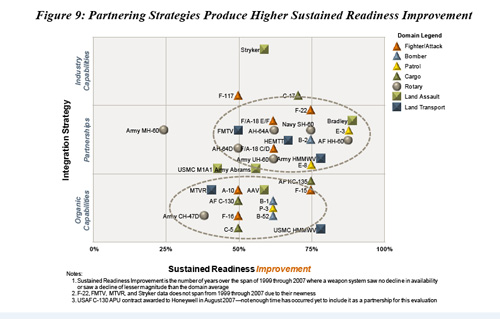

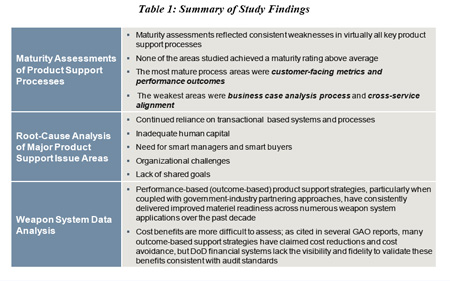

The report identified a number of challenges to be met to improve product support. Among the most important was underscoring support for the impact which Performance Based Logistics (PBL) has had on the working relationship between government and industry. PBL has demonstrated widespread success as reflected by the report’s finding that “the most mature process areas (in product support) were customer-facing metrics and performance outcomes.” The report did recognize the problem of what the GAO has called the “inauditability” of PBL cost savings: more care needs to be taken with analytic rigor, tracking, and record keeping. “Cost benefits are more difficult to assess: as cited in several GAO reports, many outcome-based support strategies have claimed cost reductions and cost avoidance, but DOD financial systems lack the visibility and fidelity to validate these benefits consistent with audit standards.”

Adopting a New Business Model

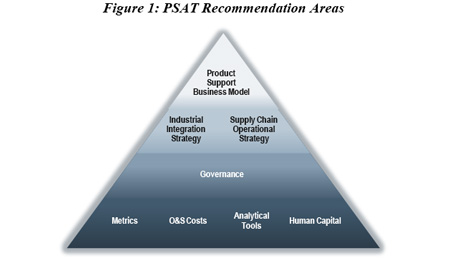

The report made eight principal recommendations. The authors shaped those recommendations into a pyramid model, the top two bands reflecting strategic priority initiatives, the third band reflecting the critical governance processes necessary to provide product support accountability across the life cycle, with the base of the pyramid reflecting the aspects, which enable the recommendations necessary to implement the higher level reforms.

At the heart of the recommendations is an emphasis upon adopting a new business model. This model would “capitalize on an integrated defense industrial base and performance outcomes to enable cost effective capability across the weapons system life cycle.”

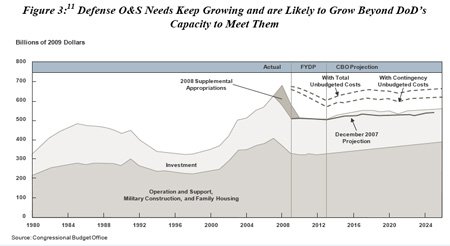

The challenge is simple: support costs are higher than the defense budget can afford for the long-term. Roughly 1/3 of weapons system spending is associated with development and acquisition, while the remaining 2/3 of the spending takes place in the sustainment tail. In order to achieve fundamental financial reform, acquisition reform must grow to include the life cycle. The acquisition of new equipment must more effectively take into account anticipated support costs, and presumably tools might be developed to more effectively choose among weapon systems based on sustainability advantages. It’s about making decisions that integrate the breadth of considerations in the industrial base, balancing the financial trade-offs between now and the future, and pushing for cost-effective performance for the life of the weapons system.

The report also underscores that effective partnering has enabled performance to be enhanced, even if costs savings cannot always be proven.

***

THE INTERVIEW

Taking Care of the “Neglected Stepchild”

Randy Fowler first underscored that logistics support and sustainment are crucial factors affecting concepts of operations, readiness and the defense industrial base. “Too often life cycle sustainment is the neglected step-child. But now with the press of deployments and a new Administration likely looking to squeeze savings out of the budget, logistics support and sustainment are becoming prime time issues.”

At the heart of logistics and sustainment are readiness issues. “If the military and its equipment are not ready to fight, its ability to influence events is significantly reduced. And the ability to count on availability of weapons systems is a significant aspect shaping concepts of operations worldwide.”

But at the same time, too often sustainment is thought of as the last mile of acquisition efforts. “We tend to think in linear ways about the cycle of acquisition going from R and D (research & development), to prototypes, to manufacturing, to production, to platforms readied for deployments and THEN support and logistics systems. In reality, we need to think in continuous process terms. Technology development, manufacturing, production and sustainment are all part of a continuous 21st century industrial base process. You are always developing a bit, , manufacturing a bit, sustaining a bit and pushing modifications and upgrades of a weapon system and then eventually jumping to the next leap-ahead new system capability. This is why you need to think holistically about manufacturing and sustainment.”

Striving for S2 Transparency

In Randy Fowler’s view, the sustainment challenge is part and parcel of the industrial base issues. “In effect, there is an S2 process. The manufacturing supply chain (S1) and sustainment supply chain (S2) are part of the same effort. To sustain you have to have supply chain transparency. To manufacture you need to have transparency and control over supply chain issues. This is why industry is such a crucial partner in the sustainment process. Indeed, if you cut them out in sustainment, this will have significant impacts on the supply chain, manufacturing, and the ability to have an effective defense industrial base.”

Randy Fowler went on to discuss the challenges facing performance-based logistics. “Perhaps we need another term, but the reality is that the sustainment process is about performance, and performance measured by availability of platforms and weapons. The regular and ongoing negotiation between industry and government in shaping performance-based metrics is at the heart of what has improved sustainment through PBL. It is not always easy to show cost savings; but it is not difficult to show readiness, reliability, and cycle time improvements.”

Towards a Balanced Partnership

In the report, the authors underscore the need to move forward in shaping the next phase of PBL. As one of Randy Fowler’s staff members commented, “The top of the pyramid is crucial in the governance process. The re-shaping of an ever more effective business model is salient. We need to improve cost measures for both the government and industry. But the attention seems to be devolving to measurements of cost rather than focus on the VALUE from improvements in readiness.”

In short, the challenge is as Ash Carter underscores: “the industrial sector is not something you turn on or off.” Randy Fowler expanded on the Carter comment: “You need to get balanced and integrated contributions out of both the public and private sectors and to get effective long-term con-ops shaping the partnership. Both the public and private sector are integral to delivering sustainment in 100% of our weapon system platforms. Our DoD PBL strategy has been effective at driving public-private partnerships in the past, and it was named performance -based for a reason; we think we have gotten value, but new methods and ways ahead are certainly needed to improve confidence in the cost benefits. That is the point of the whole report.” Randy Fowler concludes.

———-

***Posted February 5th, 2010