At the Farnborough Air Show, MBDA held a media briefing providing an update on the Team Complex Weapons initiative (“Team CW”) and the way ahead.

The business model is of interest, not only for shaping a key ally’s approach to shaping future capability but in terms of being a potential harbinger for how MODs will handle efforts to maintain capabilities in the face of fiscal stringencies.

Lord Drayson in his formulation of the defense industrial strategy forged a number of initiatives, one of which was Team CW. The idea was to bring MOD into closer partnership with its weapons providers and supply chain to shape evolving capabilities in the industry with an eye to enhanced efficiencies but at the same time ensuring UK operational sovereignty in this key area of future military capability.

The baseline agreement was signed in June 2006 between MBDA, QinetiQ, Roxel and Thales UK as well as other members of the weapons supply chain to work with MOD in shaping development of future weapons. The idea has been to share risk, guide investment and clarify early for MOD what procurement choices are optimal for its point of view.

At the heart of the concept is to try to bridge the gap between industry and MOD in reducing risk and enhancing effective procurement. Obviously there are a number of challenges ranging for Intellectual Property ownership, investment sharing between government and diversity of private sector competitors to the question of the relationship between Team CW, MOD and the companies, such as Raytheon who are outside of the arrangement.

A next phase in the evolution of the Team CW arrangement was reached in March 2010 whereby MOD “commenced implementation of the CW sector strategy by signing a partnering agreement with the first of the Team CW prime contractors, MBDA UK. This agreement is know as the Interim Portfolio Management Agreement (PMA-1). Under the agreement, the Ministry of Defence and MBDA UK signed a Through Life Enabling Contract (TLEC) with its first package of work worth £330M for the development and manufacture of two of the six Team CW launch projects and to conduct further assessment work on two projects.” [1]

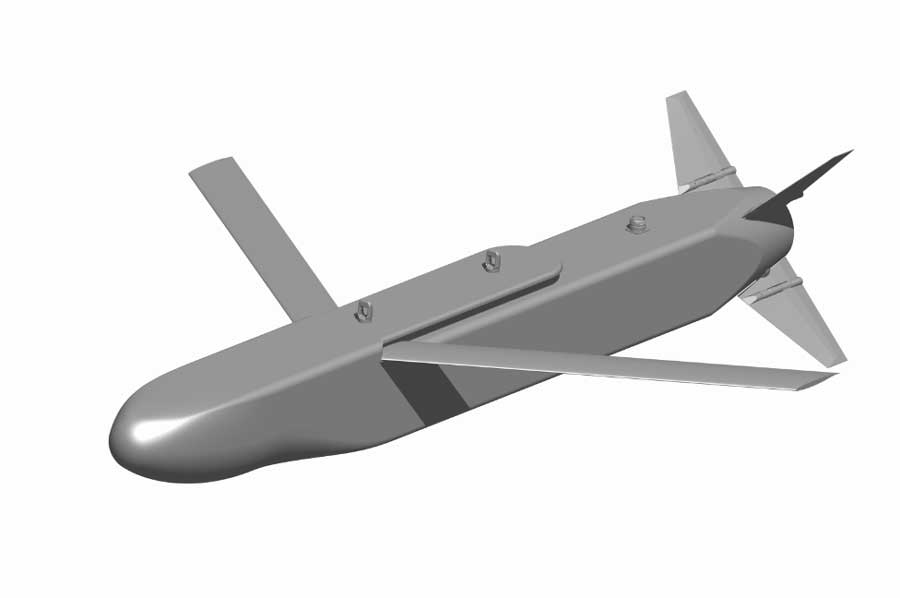

One of the work packages is for SPEAR Block 2 Capability, which builds on the Brimstone Urgent Operational Requirement to provide “fast jets with a very precise and discrete ground attack capability whilst the Fireshadow program will provide a new Loitering Munition capability.” [2]

The MOD release goes on to add “the Portfolio Management Agreement establishes a joint governance and management structure in order to deliver the future needs of the CW sector. This joint governance will manage the delivery the portfolio of projects to challenging Performance, Cost and Time parameters including effective risk, opportunity and incentivization management approaches.” [3]

And a further aspect underscored was “one of the key elements of the Agreement is an ability to flex the output of the contract to reflect the changing needs of UK forces. This approach has been developed through assessment phase and places the agreement in good position to respond to future shifts in requirements.” [4]

In a separate release (Team Complex Weapons [Team CW] Key Facts, July 2010), the approach was characterized as being based on the “delivery of three high level requirements: improved, affordable and swiftly adaptable military capability, operational sovereignty of UK weapons, greater efficiency and improved value for money.” The document went on to emphasize that “the development of a number of families of weapons” will be highlight “which will benefit from the use of modular technologies across the range, underpinned by a stable pipeline of funding managed at sector and portfolio level. On this basis the approach will provide stability to the sector in return for greater flexibility to the MOD and sustain indigenous UK industrial skills and capabilities required for operational sovereignty.” [5]

At the media briefing by MBDA, an update on the business model was provided. When asked the benefits to MOD of such a model, one of the MBDA briefers underscored that “MOD and industry were provide a much better insight into the weapons we are buying, why we are buying them, whether we need them and generally brings into sharper focus the platforms on which we will deploy them.”

The briefers were asked whether they thought the Team CW approach might be the harbinger of other such arrangements in the face of growing financial pressure. The response was to suggest that this might be the case or as it was put by the briefer, “Team CW is a significant enabler to deal with these (stringent financial) circumstances.’”

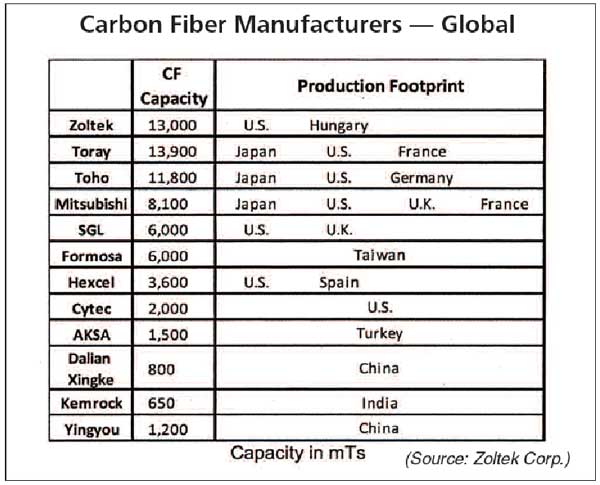

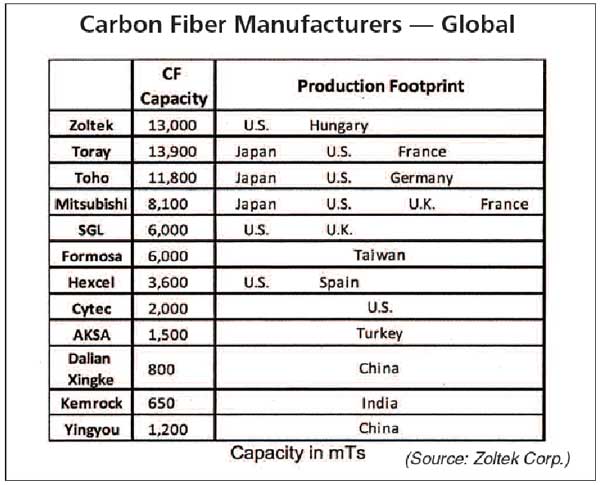

Quite obviously one of the tensions is between the creation of a teaming arrangement which shapes an MOD-Industrial front end which reduces competition and the need to remain open to benefiting from global sourcing in providing best value to provide the materials and subsystems for Team CW. As the briefers discussed the problem, they suggested that the challenge is precisely where the crossover point lies between Teaming collaboration and competitive supply chains. As one briefer commented, “It is clear that access to the global supply chain is crucial, but it is difficult to work that out at the top levels if operational sovereignty is the core goal.”

In a recent RUSI overview on Team CW, MBDA’s Steve Wadley emphasized that

Since the formation of TEAM CW, MoD and MBDA, together with the other Team CW members, have worked hard to improve the ways they work together. These changed behaviors include joint working at project and portfolio level, and openness and transparency on all issues… Aligned objectives, joint incentivization and joint technical and progress reviews between the DE&S and Industry teams have create a much more constructive, trusting and supportive problem-solving environment.

And at a Raytheon press briefing at the Farnbough Air Show, Dr. Taylor Lawrence, President of Raytheon Missile Systems raised “concerns about the industrial policy of the UK, [which is] preferentially treating one of our competitors, MBDA, for [the] CW [program].”

As the West faces the challenge of shaping common missile defense capabilities a key question to resolve will be the relationship between approaches such as Team Complex and the American firms which will shape future US missile defense capability. In a constrained financial environment, how to shape effective teaming arrangements which are open to tapping effectively and efficiently global capabilities?

———

[1] to [5] All quotes have been taken from “UK MOD-MBDA Bilateral Agreement: Key Facts” (July 2010).

———-

***Posted on September 7th, 2010