Friedrichshafen/Dresden/Boston/Seville, 27 October 2020 – An international team led by Airbus Defence and Space (Friedrichshafen, Germany) with scientists from Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM (Dresden, Germany), Boston University (Massachusetts, USA) and Abengoa Innovación (Seville, Spain) has successfully demonstrated the production of oxygen and metals from simulated lunar dust (regolith) with the Airbus-invented process named ROXY (Regolith to OXYgen and Metals Conversion). Airbus believes ROXY could revolutionise human space exploration.

After two years’ development the breakthrough came last month, during a series of laboratory tests at Fraunhofer IFAM. Oxygen was extracted from a sample of simulated lunar dust. This is a small first step, but the way towards an operational system is now clear. Oxygen is indispensable for all human space activities, and this new ROXY production method, which directly uses Moon dust could revolutionise human activities on the lunar surface.

“This breakthrough is a massive leap forward – taking us one step closer to the holy grail of being able to sustain long term living on the Moon,” said Jean-Marc Nasr, Head of Space Systems at Airbus. ”ROXY is proof positive that collaboration between industry and world leading scientists can bring huge tangible benefits that will continue to push the boundaries of future exploration.”

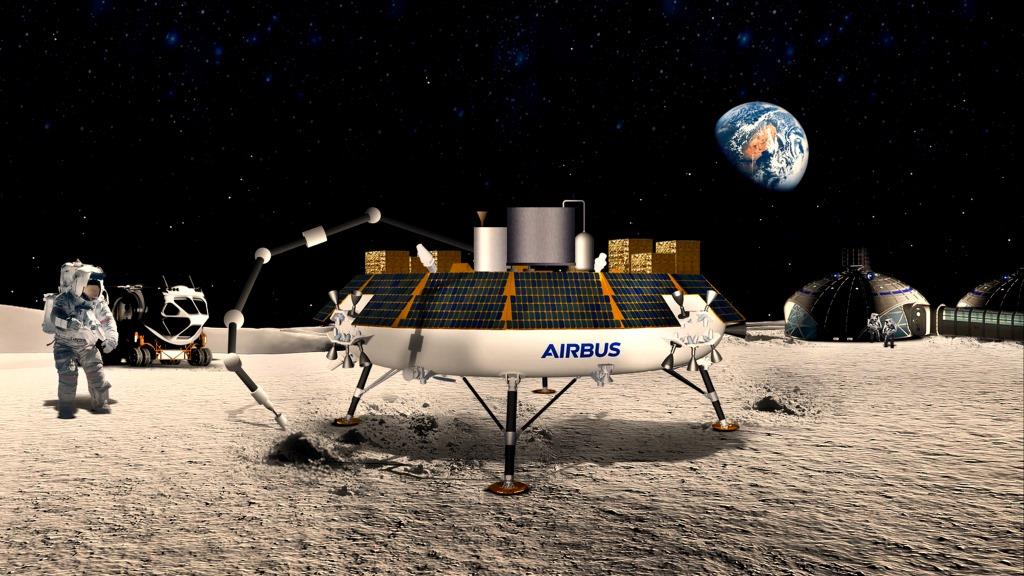

ROXY enables the design of a small, simple, compact and cost-efficient regolith to oxygen and metals conversion facility, and is therefore ideally suited to support a wide range of future exploration missions. Not requiring additional materials or consumables from Earth – except the ROXY reactor itself – this could be the heart of an integrated value chain using additive layer manufacturing to produce a wide range of products ‘Made on the Moon’. These could include metals, alloys and oxygen. Combined with lunar ice, it would even be possible to produce rocket fuel from ROXY metal powder.

On Earth, ROXY opens a new pathway to drastically reduce the emissions of greenhouse gases that result from production of metals. With current technologies, global metal production causes severe environmental impacts. Steelmaking accounts for about 5 percent of the total global CO2 emissions. Many metals are obtained with processes that emit significant amounts of the environmentally harmful perfluorocarbons (PFCs). Since ROXY is essentially an emission-free process these environmental impacts could be reduced, providing a significant contribution to the UN sustainability goals – another example of how space technologies can improve life on Earth.