In the 21st century, a defense prime contractor delivers the final product.

But increasingly, he does so through managing a supply chain, which is rooted in commercial and military supplies.

These blended products feed into the company responsible for final delivery of a product to a customer, and these products evolve over time as data is obtained to determine mean failure rate of the parts or other operational indicators of success.

The manufacturer managing the Final Assembly Line or FAL obviously needs access to the information on the performance of the final product in operational conditions and detailed information on the parts performance. This way the products can be improved so that the final product, in turn, is produced of high quality or fidelity over time.

This is why the prime contractors are so involved in the logistics side of the supply chain and not just on the manufacturing side. This is also why systems like performance-based logistics have been adopted, whereby the OEM as prime contractor is involved in delivering performance guarantees for the product and involved in managing the supply chain from production through logistics support.

What remains to be determined on a case-by-case basis is the relationship between the Ministry of Defense, the service using the product, the military force operating the product and the role of the prime contractor over time in the logistics system.

No one MOD or service follows exactly the same pattern.

But the broad challenge is to accept a key role of the prime contractor but to determine the best or optimal relationship between the services, and the prime contractor and companies along the supply chain in determining the most effective solution for that nation and its military services.

At the Airbus Trade Media brief held at the end of May 2013, Phillipe Galland, the head of Airbus Military services, presented an overview of the company’s evolving approach to providing services. The briefing drawn on for the presentation can be seen below:

The briefing highlighted Airbus Military’s approach to working upwards on the value chain in shaping its approach going forward.

But with regard to both the A330MRTT and the A400M, two programs which are multinational in reach, and with 21st century supply chains, the Airbus Military is working with its customers in a variety of ways dependent upon what those customer’s wish to see with regard to the working relationship with AM as a prime contractor.

For example, with regard to both Australia and the UK in the A330MRTT program, the customers have set up a services approach in country, which is based on a distinct approach.

With regard to Australia, Quantas Defense has been contracted by the RAAF as the provider of on site support to the RAAF with Airbus Military in the back office as the aircraft OEM. The RAAF is performing operational maintenance on the aircraft with QDS doing the deeper maintenance.

According to Quantas Defense, the company is

A wholly owned subsidiary of Qantas Airways Limited, Qantas Defence Services employs approximately 500 people. It currently provides support to a range of major Australian Defence Force capability systems including the Lockheed C-130H Hercules and P-3 Orion, the Boeing B737-700IGW and Bombardier Challenger CL604 Special Purpose Aircraft, Sikorsky S-70A-9 Black Hawk, BAE Hawk 127 and the EADS CASA KC-30A Multi Role Tanker Transport.

The core contract is for 20 years and is a Through Life Support systems contract.

The TLS Subcontract has been established to allow Airbus Military to support Qantas Defence Services in the performance of its obligations as prime contractor to the Commonwealth of Australia for the TLS of the AAR Weapon System.

Under the TLS Subcontract Airbus Military will provide Engineering, Logistics, Technical Data, Supply and Training Support Services to Qantas Defence Services in support of the TLS Contract with the Commonwealth of Australia.

The UK case is different because Airbus Military is selling its planes to a Air Tanker, which in turn sells flight time to the RAF for tanker services. The core concept is that Air Tanker provides the capital to buy the planes, and operates the planes for the RAF on a time leasing basis.

According to Air Tanker:

The aircraft support the Future Strategic Tanker Aircraft (FSTA) Contract, awarded to AirTanker by the UK Ministry of Defence in 2008. The FSTA programme delivers all the associated support services including aircraft maintenance, training, infrastructure, fleet management and ground services and will ultimately use 14 of the specially converted A330-200 aircraft. The program aims to provide a safe, reliable and efficient air transport and air-to-air refueling service over a 24 year period (from delivery of the first aircraft).

Obviously with such an approach, Airbus Military operates as the OEM providing parts and various inputs to ensure that Air Tanker keeps the flight up and running and with high reliability and availability performance. The AM subsidiary is located in the Air Tanker Services facilities and provides, among other things spares.

The A400M approach is a work in progress, whereby the services are sorting out their role, the local service contractor’s roles and the role of AM in providing support.

The most advanced of the service approaches is that of France as the aircraft is being introduced into service this year.

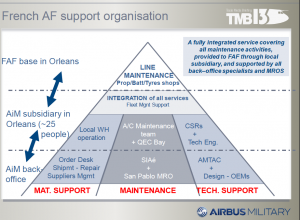

The graphic below shows the structure as of May 2013, in which the French Air Force is planning on doing the line maintenance of the aircraft with AM responsibility for integrating the services to provide for fleet management support.

In short, the services approach of Airbus Military is a work in progress, one which will be shaped by how customers determine the relationships with prime contractors building 21st century systems.