2017-10-17 By Robbin Laird

The Indian Air Force is about to launch competition to add new fighter aircraft.

This would be in addition, to the acquisition of 36 Rafale fighter aircraft, already in place.

The Indian Chief of Staff of the Air Force has indicated that the IAF will buy additional Rafales but also add a new a single engine jet to modernize its fighter force.

The frontrunners in the single engine competition are Saab’s Gripen and Lockheed Martin’s F-16.

Such a competition is not simply a platform competition, but a capability one as well in terms of the industrial and combat ecosystems associated with each aircraft.

There are clear differences, not the least of which the F-16 is combat proven and being upgraded by several F-16 users, and the Gripen is not combat proven and is being upgraded almost completely by the Swedish Air Force.

If the Gripen were to be selected by the IAF, the Indians would undoubtedly pay the lion’s share of upgrades in the future.

The F-16 being offered is what Lockheed and USAF are calling the Block 70, which has significant upgrades in terms of avionics, sensors and radars.

Not only is the aircraft being significantly modified in terms of what the aircraft is capable of doing in the battlespace, but also in terms of how the pilot workload is being changed by the new systems onboard.

New data management, sensors, processing and displays allow for significantly enhanced workload efficiencies for the Block 70 F-16 pilot

The differences between what an F-16 and a Gripen means for the future of the IAF goes far beyond a platform discussion.

It is really the strategic impact of the global F-16 enterprise and its ties to the evolving F-35 renorming air combat enterprise versus the Gripen as a Swedish air platform, which is flown by a very small number of air forces globally, and certainly not cutting edge ones.

For the Indian Air Force the choice is rather stark if one takes an enterprise or global combat learning curve point of view.

The F-16 is flown by a great number of Air Forces and key parts are built worldwide. This means that India is not tied to the United States and its operational or manufacturing experience.

Rather, the F-16 built in India could leverage a global enterprise as well as expand its global working relationships.

In contrast, purchasing the Gripen does tie the Indians tightly to Sweden and the partnerships they have had, many of them American, in building their combat aircraft

For example, the UAE Air Force flies both the most advanced F-16 to date, the Block 60, as well as French combat aircraft. The Indians flying Rafales and F-16s might well find a working relationship with the UAE in shaping interactive concepts of operations or the development of mutually beneficial technology to enable their air combat forces.

The “Made in India” part of the F-16 engagement would clearly be about opening the Indian air combat aperture to a variety of F-16 global partners.

The SAAB “Made in India” would be more about literally making a Swedish Aircraft in India for Indians with little prospect of amortized modernization cost by other Gripen partners or the Swedes for that matter.

And that brings up the impact of USAF modernization as well.

The USAF is structurally modernizing a significant part of its F-16 fleet with the so-called SLEP program that adds 50% additional service life up to and beyond 12,000 flight hours.

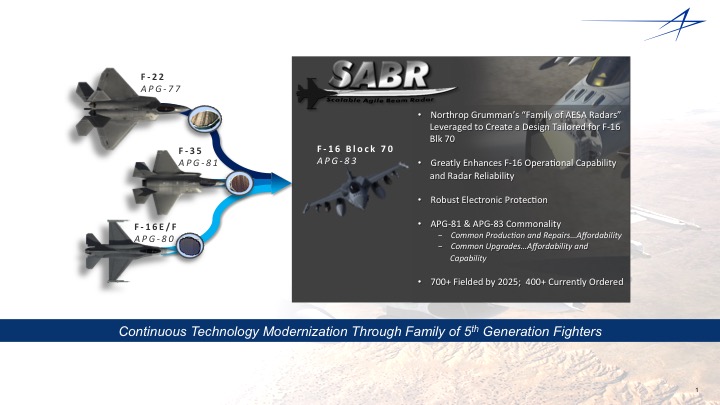

At the same time, they are introducing an advanced Northrop Grumman radar, the APG-83.

The radar on the F-16 Block 70 and the spill over effects from the F-35 program as well are important considerations when buying a Block 70.

The software on the Block 70 radar has more than 95% in common with the APG-81, the AESA radar that’s on the F-35.

And the hardware is 75-80% in common.

Collectively, there is about 85-90% in common between the Northrop radar on the F-35 and the F-16 Block 70.

And this obviously has a significant impact upon both the path and cost of modernization.

The U.S. and the F-35 partners will invest significantly in the evolution of the F-35 radar, which will have an impact as well on the Block 70 radar modernization as well.

This radar, the latest of four fighter aircraft based electronically scanned array fire control radars from Northrop Grumman, shares much in common with the F-35 radars as well, which means that when it comes to the evolution of the sensor-EW-command functions provided by advanced AESA radars.

The Indians would be benefiting from USAF combat learning with the new systems and as well as those global partners engaged in a similar modernization effort.

Beyond the USAF, this may well have been part of the decision making process with air forces in Taiwan, Singapore, South Korea, and currently being contemplated by Greece that have led to several hundred F-16 upgrades with this radar.

And it is clear that the impact the F-35 will be significant upon the evolution of air combat, something I have labeled, the renorming of airpower.

An Indian Block 70 clearly would be a beneficiary of this evolving air combat learning process as new radars and sensors enter the air combat force, with the new Northrop Grumman radars as an open ended evolving combat capability.

Put in blunt terms, the IAF could choose a platform qua platform in terms of its organic capabilities at the time of acquisition or it could buy a enterprise enabled platform which is part of a global enterprise, with several key air combat forces world wide, and flying with key elements of the ongoing air combat revolution driven by the F-35.

Made in India could be part of engaging in the global enterprise or it could be narrowed down to assembling a combat aircraft in India itself as the focus of effort.

Being part of a global F-16 force has many other advantages.

There are many F-16 pilots worldwide; there are a variety of training centers; and if the IAF needed more aircraft in a crisis they could go to an F-16 partner and find ways to lease aircraft as needed as well.

With a global inventory, there is always a possible of a rapid plus up.

It would be difficult to do this while attempting to dip into the global pool of Swedish, Thai, South African or Brazilian Gripens.

The enterprise advantage clearly seems to go to the F-16 and this advantage would seem as well to have been augmented by the different partnering arrangements, which Lockheed and SAAB have taken.

SAAB is partnering in India with a company with no experience in aerospace, namely the Adani Group.

It is a partner that would clearly help with the Made In India part with regard to investments domestically.

As the Adani Group website highlights:

The Adani Group is one of India’s leading business houses with revenue of over $11 billion.

Founded in 1988, Adani has grown to become a global integrated infrastructure player with businesses in key industry verticals – resources, logistics, energy and agro. The integrated model is well adapted to the infrastructure challenges of the emerging economies.

Adani Group’s growth and vision has always been in sync with the idea of Nation Building. We live in the same communities where we operate and take our responsibility towards contributing to the betterment of the society very seriously. Through Adani Foundation, we ensure development and progress is sustainable and inclusive; not just for the people living in these areas, but the environment on the whole. At Adani, we believe in delivering benefits that transcend our immediate stakeholders.

https://www.adani.com/about-us

What is not so clear is what such a business brings to the question of force modernization and accelerated introduction of combat aircraft?

This appears to be a significant differentiator between Lockheed and Saab as the Government of India moves forward with this challenging and ambitious project.

Recently, I had a chance to discuss the F-16 opportunity with India with the Lockheed Martin Aeronautics head of F-16 and F-22 business development, Randall Howard, during a visit to Fort Worth to view and discuss the final assembly line for the F-35.

Howard has had many years of experience working with allies in acquiring and operating advanced aircraft with allies, notably both with the F-16 and the F-35. He spent 20 years with the USAF and now 10 years with Lockheed Martin working with allies on air combat issues.

According to Howard, the F-16 line is closing at Fort Worth, with the last F-16 produced at Fort Worth being for the Iraqis. Now a “hot line” is being established at the Lockheed Martin facility in Greenville, South Carolina which will build up to 19 new F-16s for Bahrain’s Air Force.

This means that the F-16 partners will see new work generated as well.

“Key elements of the F-16 are built by the partners, in Greece, South Korea and Israel and the Bahrain program and the standup of the new facility in Greenville substantiates the continuing customer demand for the F-16 and will drive new demand for our partners.”

Howard pointed out that this meant that India would benefit from the new standup as well as the working relationship with F-16 industrial partners in moving the sole production line to India itself, if the F-16 were chosen by the IAF.

The performance of the F-16 certainly is not in question; nor the existence of a significant F-16 global user base.

“The success of the F-16 is unmatched as a program in terms of bringing countries together, shaping relationships which have delivered significant combat capability, and an unparalleled track record on delivering bombs on target for the past three decades in the US and partner air forces.”

We then discussed the different ecosystems so to speak of the Gripen versus the F-16.

“One of the difference between F-16 and our global competitors is economies of scale that drive industrial business case realities.

“Where competitors have fielded a few hundred aircraft globally, the global F-16 community includes more than 25 countries flying approximately 3,200 of those 4588 F-16s that were produced; 3200 of them are flying today.”

“The U.S. Air Force and other allied Air Forces are upgrading their F-16s and many of these aircraft are being service life extended out to 12,000 hours and are going to be flown for 30 more years.

“This means that there is a clear opportunity for industry to be part of that modernization process, which would clearly be available to India as well.

“Our recent joint announcement with TATA during the Paris Air Show provides an exceptionally strong, experienced, and proven team capable of delivering on the challenges of establishing F-16 global production in India and building a defense ecosystem that supports the global demand.”

The F-16 is also part of entire upswing in the capabilities of legacy aircraft as new systems are added which have an additive impact on the combat capabilities of the legacy aircraft as well as change the workload and work processes of the combat crew as well.

If one looks at the Canadian Aurora variant of the P-3, or the KC-130J, as examples, new capabilities have been added to what looks like a legacy airplane but it does not perform in the same manner at all.

This clearly applies to the F-16 as well – it may look like a legacy F-16 but it has only aerodynamics and some core combat performance characteristics of the airframe in common.

Otherwise, it is evolving into an enhanced 4th generation combat capability integratable with fifth generation renorming combat aircraft.

And the process of evolution will continue.

Given the USAF’s commitment as well as the global partners who are still and will continue to use the aircraft modernization and upgrades are guaranteed as part of any Indian F-16 experience.

As part of the USAF F-16 SLEP program, they are enhancing the expected operational life of the air frame as well.

“It is certified at 8,000 equivalent hours.

“The USAF has contracted Lockheed Martin to evolve the airframe to a 12,000 equivalent hour capability.

“We’re “productionizing” the airframe changes.

“We’re going to build these new Block 70s for Bahrain and the customers that come behind them, to be able to operate through to 12,000 hours.

“This delivers about 50% more service life than any other aircraft in its class.”

In short, the F-16 provides India with a strategic opportunity not just to add new platforms, but to shape a more effective global engagement in the innovations underway by the U.S. and its partners in evolving air combat capabilities.

Editor’s Note: See our earlier piece by Danny Lam on the F-16 and India.

https://sldinfo.com/f-16s-built-in-india-thinking-through-the-strategic-impact/

http://www.indiandefensenews.in/2016/08/why-lockheed-martins-bid-to-build.html

We highlighted the following with regard to Dr. Lam’s piece on the F-16 for India:

Editor’s Note: One does not have to agree with everything, which Lam has argued in this article, but there clearly are three key takeaways, which are very significant for India.

First, what are the benefits of having a manufacturing line for the most widely used 4th generation aircraft?

How can one leverage a global user base and support or supply such a user base?

Second, how will the Indian armed forces connect their platforms?

For the Indian Air Force this is absolutely critical given their propensity to buy a wide variety of platforms.

Third, given the experience Indians have in the software business, how can this be transferred to the defense business, notably in terms of shaping a combat cloud for the armed forces?

How will India shape a connected combat force which can overmatch the Chinese forces?

Fourth, if India can build real competence on connecting its disparate air combat force, there clearly will be markets globally for such a competence and again if one is building an aircraft which is already the largest 4th generation deployed air combat aircraft, then that simply opens up significant market opportunities.

Editor’s Note: The slideshow highlights photos of aF-16 Aerial Demonstration Team during the opening ceremonies of Aero India 2017 at Air Force Station Yelahanka, India Feb. 14. (U.S. Air Force photo by Capt. Mark Lazane)