2013-11-03 By Robbin Laird

During my visit to Cameri in October 2013, I had a chance to visit the Cameri facility with Fred Napurano, the Italian Program In-Country Operations Lead for Lockheed Martin.

Napurano is the key person interacting with Alenia Aermacchi (AAeM) to assist in the standup of the facility.

The visit as well as the discussions with Napurano underscored the sense of enthusiasm at the facility in shaping a new US-European approach to building military aircraft and shaping a future sustainment facility for the F-35 operating in the region.

While visiting the plant, I saw several interactions among the Italian workers as well as between the Lockheed and Alenia worker, which clearly demonstrated the interest in working together in shaping a futuristic venture.

Napurano noted several examples of such enthusiasm and noted, “several workers had volunteered to come from Torino (an Alenia Eurofighter facility) and to work on the program. This means that whether by car or car pooling or by train, workers are coming 60 to 90 minutes each way from Tornio to work at the plant.”

Napurano highlighted that the Italian government had taken a broader view when building the facilities in Cameri. “Rather than just standing up a limited facility focusing simply on assembling their own planes, the Italian government took the broader view and built out capacity for other Europeans and to shape an infrastructure able to encompass fleet sustainment as well.”

The facilities at Cameri are designed to be very flexible in terms of providing for future sustainment engagements by allies.

“The facilities are very flexible for maintenance. There are no fixed bays but are open areas where the client can figure the support area as they might wish to support their combat aircraft.”

And it is obvious as well that as LM personnel teach Alenia personnel that it is not a one-way street.

“Alenia has been making airplanes for a long time. And the adaptation of techniques transferred from Fort Worth is seeing changes as the Alenia personnel not only improves on these techniques but also suggest different approaches.

And these approaches can provide significant future benefit to the global program as well.

An important aspect of the manufacturing process is digital thread manufacturing and with the time differences between Fort Worth and Cameri, a key challenge is to translate digital changes being made in Fort Worth into changes on the Italian line as well.

“We communicate daily with Fort Worth to ensure synergy in the process of manufacturing. It is a challenge. They become much more detailed as the process continues.”

There obviously is a learning curve involved in the process.

“Translating from Fort Worth to Cameri is a two way process. And we have to adapt the Italian process to EU laws and regulations which is an additional challenge we deal with here.”

Napurano highlighted the importance of building relationships in the production process of trust and mutual understanding.

“It is not just a question of getting to yes; it is about getting to good quality finished product. That will only happen with demonstrated success in working through the problems on a day-by-day basis.”

See also the following:

https://www.sldinfo.com/cameri-and-the-f-35-building-out-a-new-manufacturing-facility/

https://www.sldinfo.com/an-update-from-cameri-on-the-cameri-f-35-campus-october-2013/

https://www.sldinfo.com/building-out-an-f-35-fleet-sustainment-center-in-italy/

https://www.sldinfo.com/visiting-the-italian-air-ministry/

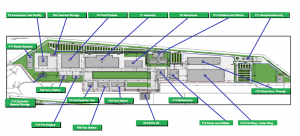

Located on an Italian Air Force base used for logistics, the Italian government under the management of Alenia Aermacchi (AAeM) has built a 22 building facility to support the F-35 program.

The support comes in three parts.

- First, there is a Final Check Out and Assembly facility, for assembling Italy’s As and Bs, as well as other European F-35 partners, initially the Netherlands.

- Second, there is a wing construction facility with Italy building a minimum of 835 full wings for the F-35 global program.

- Third, with the 22 buildings of more than a million square feet of covered work space comes significant space to build out support for F-35s operated by the US and allies in Europe.

- With the Mediterranean and the Middle East as a busy operational area, the Cameri facility can provide significant operational support to the F-35 fleet operating in the area.

These photos show workers at the FACO working on the first jet.

The workforce is a mix of older and younger workers, and provides a significant boost to the future of Italian aerospace and defense.

[slidepress gallery=’cameri-and-the-f-35′]

Credit Photos: Alenia Aermacchi (AAeM)

According to Finmeccanica CEO Alessandro Pansa, in a recent comment during an audit at the Chamber of Deputies Defense Commission:

With the participation in the F-35 program “the Italian industrial system brings home potential returns for $ 10 billion” and occupational returns will exceed 5,000 units.”

The development of these potentialities “depends on our capability to use the infrastructure which have been created to build components and to provide maintenance related to avionics and electronics both for the European aircraft and the US aircraft based in Europe.

There’s no other European plant with the same requisites as our plant in Cameri”

Pansa underscored that 90 Italian companies are involved in the program and so far contracts have been subscribed for $765 million.