By Dr. Harald Malmgren

Credit: China’s exceeds expectation as economy expands by 8-8,

Credit: China’s exceeds expectation as economy expands by 8-8,

http://trendsupdates.com, January 2010

09/30/2010 – Resurgence in economic nationalism and protectionism is unfolding in the US. President Obama’s bold promise to “double US exports in the next five years” has raised many eyebrows, as questions multiply about how this might be achieved.

In the meantime, recent Obama Administration statements have emphasized commitment to more aggressive enforcement of existing trade agreements. The USTR (United States Trade Representative) has for several decades been the primary Executive Branch proponent of more liberal trade policies and continued multilateral trade liberalization.

Under President Obama, the USTR and other cabinet officers have instead argued for priority attention to implementation of import restrictions, through revised interpretation and regulation of antidumping and countervailing duty actions and other restrictions on cross-border flows. While it is argued that this is simply a matter of “enforcement” of existing law, the reality is that interpretations of existing law and appropriate remedial actions are being altered to ensure greater restriction on imports.

In this area of law governing “unfair trade practices,” there has long been broad room for discretion in applying remedial action. Exercise of such discretion to bring about limitations on imports has varied significantly over recent decades, but under the current Administration has become far more protectionist in intent.

There has recently been a resumption of Presidential interest in the long-pending South Korea-US FTA, under pressure from US exporters. However, the Administration still seems to be unable to function without acquiescence of industrial unions that argue that they are affected. Until 1967, American unions, including the industrial unions, supported more open international trade. Since then, industrial unions opposed trade liberalization agreements.

Since the 1960’s, all Presidents have nonetheless politically overridden union opposition and continued to seek international agreements to liberalize trade. In the last five decades, in spite of domestic political opposition driven by industrial unions, the Congress continued to give approval of multilateral trade agreements that were endorsed by Presidents.

Now, in a period of extended economic slump and high unemployment, the current President has been unusually responsive to pressures from industrial unions to avoid new international commitments and instead focus Administration attention on import restriction.

In this context, President Obama has gone along with G-20 commitments to seek success in another round of negotiations to liberalize trade in the WTO, but in practice his Administration has given virtually no attention to the WTO. Rather, trade policy has been relegated to the bottom of a very long list of priorities, most of which are determined by domestic priorities.

The most important political driver behind enhanced import restrictions has been US domestic political attention on China. There has always been some Congressional emphasis on assigning blame for domestic problems on foreign governments and businesses.

Assisting US businesses or economic segments usually requires government funding. If restricting imports can provide assistance, politicians know that the domestic cost will be spread thinly among all voters without meaningful opposition, whereas the primary cost will be imposed on foreigners, and “foreigners don’t vote.”

In the 1980’s the principal cause of trouble was believed to be Japan, giving rise to a period known in Congress as “Japan bashing.” At present, China is politically perceived as the principal challenge to American competitiveness, and “China bashing” is in fashion.

A core issue underlying the anti-China political sentiment is a perception that the exchange rate between the Chinese Yuan and the US dollar is set by Chinese authorities to provide “unfair” competitive advantage. Alongside this politically potent argument are other issues: The Chinese laws regarding protection of intellectual property are weak and fail to deter or penalize Chinese “theft” of American product and production technologies and replication of American branded products. Chinese treatments of US enterprises operating in the Chinese market are discriminatory.

However valid these and other complaints might be, the strategies of world-diversified corporations in dealing with China are changing.

First, many multinational enterprises have found that wages in the Chinese export sector have risen sufficiently to reduce the apparent competitive advantage of China for sourcing parts, components and final products for consumption in the US and Europe.

Second, recent problems in labor relations between foreign corporations and Chinese unions have reduced Chinese attractiveness as a hub for supply chain production.

Third, it is extremely difficult to maintain international quality control standards in Chinese production facilities. Multinational companies are increasingly mindful of the need to maintain quality standards in order to avoid product recalls and damaging consumer responses to faulty or toxic imports from China.

Fourth, there is little advantage to deploying advanced technology in China as it is likely to be copied and replicated by Chinese competitors, and there is no advantage in undertaking research in China as intellectual property will be pirated.

A common conclusion is that producing inside China for Chinese consumers makes sense, but that using Chinese labor and facilities to produce for sales to more advanced economies is increasingly less attractive.

Credit: Business Week, February 2009

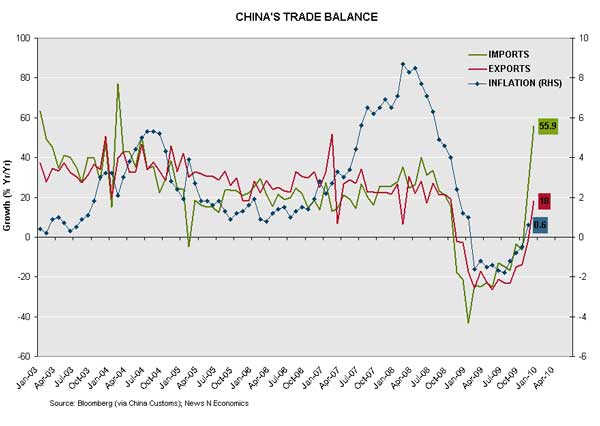

Thus, the Congressional focus of attention on imports from China as a cause of job outsourcing from the US is becoming obsolete. As for the exchange rate, the Chinese manipulation of its exchange rate was closely interlinked with Chinese reliance on exports as the primary engine of growth. Since the collapse of world trade in the second half of 2008, this export engine faltered.

The Chinese leadership recognizes the need to boost domestic consumption and reduce reliance on exports to drive GDP growth, but making the transition from almost complete dependence on exports to greater economic diversification will take several years. In the interim, the industrial export sector has suffered and labor displacement inside China has been substantial.

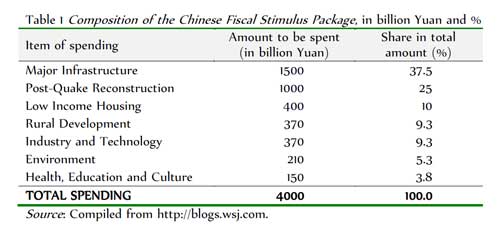

As quoted in : Vineet Kohli, The Fiscal Stimulus Package,

As quoted in : Vineet Kohli, The Fiscal Stimulus Package,

Project on Monitoring and Analysis of Budgets in Maharashtra State, March 2010

Government fiscal stimulus and an extraordinary level of Chinese bank lending mandated by the government have kept Chinese growth going since the collapse of exports in late 2008. One consequence has been overflow of extraordinary lending into many other economic sectors, including investments in Chinese real estate, commodity stockpiling, expansion of industrial capacity, investments in credit derivatives, and other “bubbles.”

Now, as world growth slows, the dependence of the Chinese economy on external drivers is resulting in economic slowdown. Given the huge artificial stimulus measures of last year, the Chinese government finds its policy responses to global slowdown limited by domestic bubbles.

As growth slowed, Chinese exports to the US have become less vital as Europe has replaced the US as number one buyer for Chinese exports. Weakening of the Euro hurt competitiveness, especially when the Yuan was pegged to the dollar. With export demand still weak, there is minimal incentive for China to encourage rise in the dollar exchange rate and strong incentive to discourage Euro weakening. “China bashing” in Congress now may have diminishing impact on US jobs, and instead generate other, undesirable tensions with China.

Source: http://4.bp.blogspot.com

Source: http://4.bp.blogspot.com

—————

Annex

CHINA ECONOMY

EU-China Trade In Facts and Figures

source: http://ceconomy.blogspot.com, July 20th, 2010