2016-03-31 According to a Joint Program Office Press Release, a new weapon has been added to the bow for the F-35 as the archer.

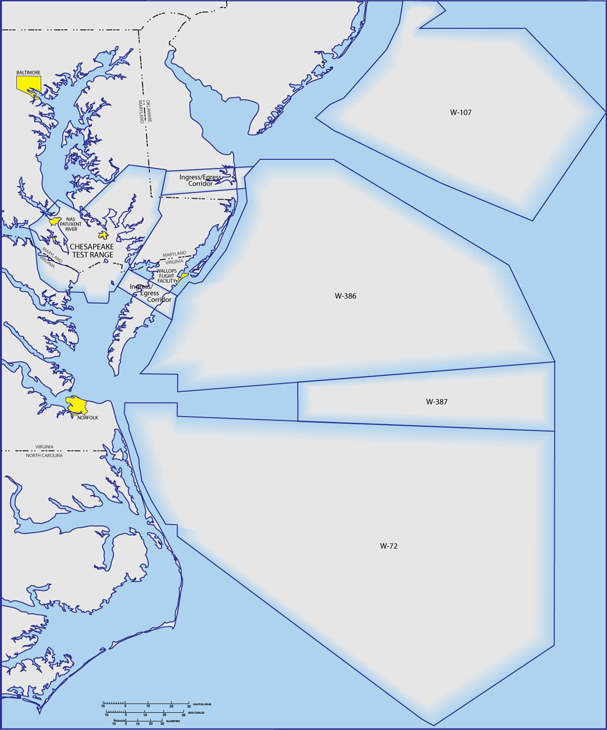

An F-35C Lightning II launched its first AGM-154 Joint Standoff Weapon (JSOW) over the Atlantic Test Ranges on 23 March.

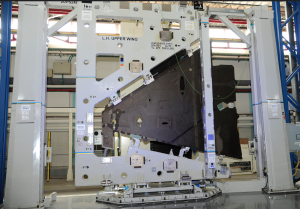

Test aircraft, CF-05, cleanly released the 1,000-pound air-to-surface guided glide bomb from an internal weapons bay, said U.S. Navy Cmdr. Ted “Dutch” Dyckman, the F-35 Lightning II test pilot who flew the mission.

The JSOW is a medium range all-weather standoff weapon that enables aircraft to remain outside the threat envelopes of typical enemy anti-aircraft and counter air defenses while effectively engaging and destroying targets. This lethality and survivability delivers a decisive advantage over potential adversaries.

The F-35 Lightning II Pax River ITF joint team, assigned to the Air Test and Evaluation Squadron (VX) 23 aboard Naval Air Station Patuxent River in Maryland, released one JSOW during the flight. The team will release additional JSOWs throughout 2016. Working on the multi-phase testing of the F-35 Block 3F capabilities, are U.S. government, military and contractor personnel, and industry partners.

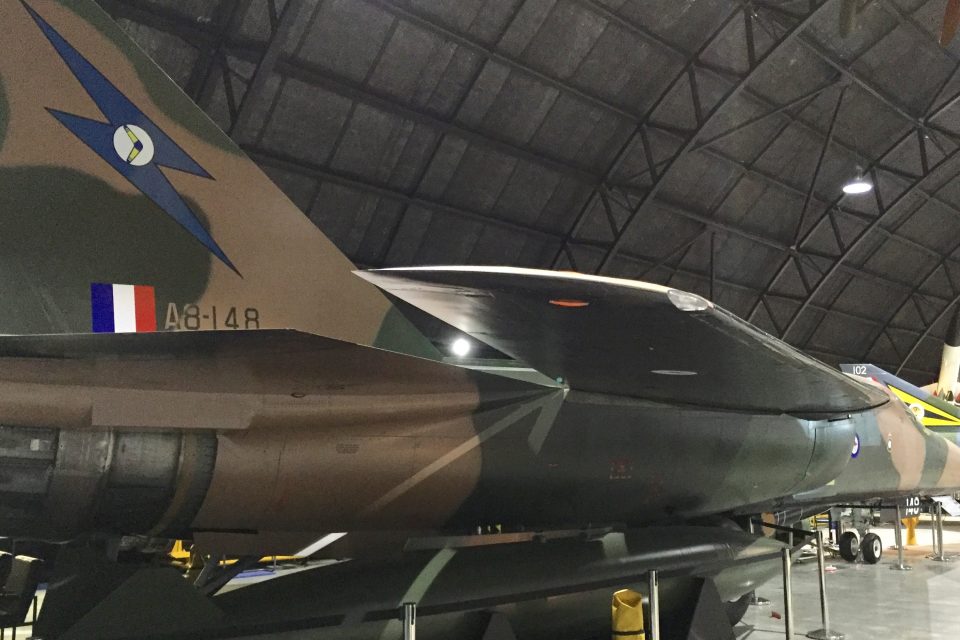

The JSOW is currently integrated and in operational status on F-16, F/A18, B-52, F-15E, B-1B, and B-2 aircraft. Integration is underway on the F-35 Lightning II. The JSOW is a joint Navy-Air Force weapons program, with the Navy as the lead service.

The F-35 Lightning II is a multi-role stealth strike fighter that incorporates low-observable technologies, advanced sensor fusion, and internal/external weapons to accomplish its missions.

http://www.navy.mil/navydata/fact_display.asp?cid=2100&tid=300&ct=2

http://www.navair.navy.mil/ranges/atr/index.htm

The F-35 is operational with the Marines and about to be operational with the USAF.

The Edwards and Pax River test teams are completely integrated in rolling out the F-35 fleet and modernizing it through software upgrades through the life cycle of the aircraft.

Developmental testing is a fact of life for operational fleets. As one test engineer commented during our visit to Pax River, “we continue to do developmental testing on the Super Hornet here at Pax.” And with more than 50,000 flight hours on the F-35 fleet and an operational squadron with the Marines, to be joined by the USAF this year and the Navy next year, the F-35 fleet has already taken off.

There are currently more than 250 F-35 pilots and 2,400 aircraft maintainers from six nations already trained and more than 110 jets are jointly under construction at the Fort Worth and Cameri production facilities.

The F-35 has become tactically operational in the USMC while the aircraft is undergoing developmental testing by the Pax River and Edwards AFB with an F-35 Integrated Test Force (ITF) for the USAF and USN .

What is not widely understood is that the ITF is managing the ongoing developmental testing for the life of the program.

With the scope, complexity and concurrent global reach of the F-35 program, a new approach to testing was set in motion.

The program is one of “spiral development” in which combat F-35 Type/Model/Series (T/M/S) airplanes emerge throughout the process to operate as effective combat assets, even while the developmental testing for all three types of F-35s continue. Put bluntly, the F-35B in the hands of the Marines is a fully “up” combat aircraft (both airframe, sensors and weapon systems) addition to the USMC Air/Ground team. All Squadron Pilots in Marines, USAF and Navy, will be backed up by the best test community in the world at Edwards and Pax. This partnership forged for decades will continue a dynamic synergistic combat way for the entire life of the F-35 Global Enterprise.

For the Lightning II, the past decade of putting together a unique, and innovative approach to shaping the F-35 fleet has paid off and has built a solid foundation for the decade ahead. As US fighter pilots and their partners generate fleet and ultimately combat experience, that will lead to never ending innovations and developmental testing.

Put bluntly, if you waiting for the end of developmental testing come back in 30-40 years. Meanwhile, the F-35 fleet will have reshaped air combat operations.

As Andrew Mack, F-35 Integrated Test Force chief test engineer put it:

“When the F-35B Block 2B became cleared for IOC, there were many stories about what it cannot do; that really is not the point. The plane will evolve its capabilities over time based on spiral development. The point is that it is a very capable combat jet at the block it has achieved already.

And the impact is immediate.

Stealth from the sea is brand new for the Marine Corps and Navy.”

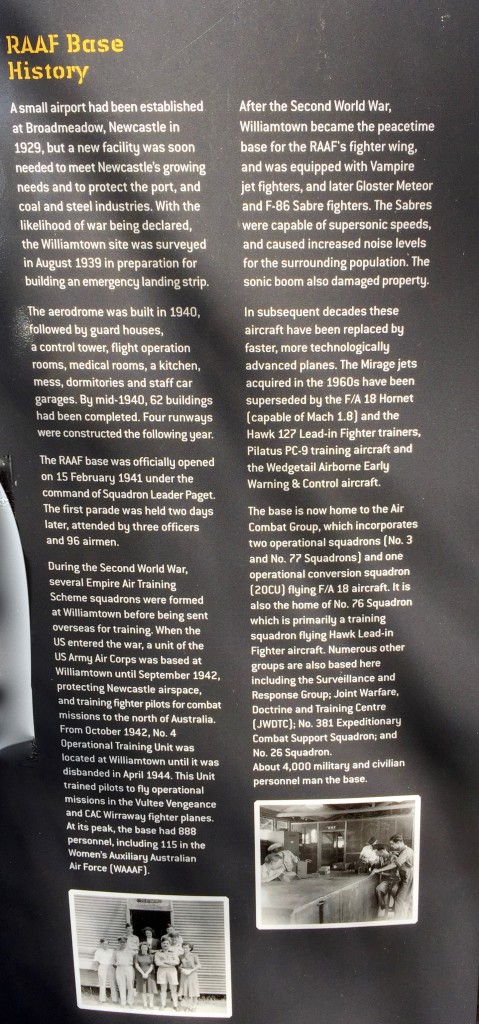

The global enterprise is a key part of what happens at Pax River. The UK is an integral part of the team, and as Gordon Stewart, UK MoD flight engineer at Pax described this powerful and productive partnership:

This is the most integrated test team I have ever worked on. As we work the way ahead, it might be a UK person, a Lockheed person, or a US government person who provides the best solution. It is a very well integrated team at the working level.

It is a very different test process than in the past, although what is happening in the F-35 program is the way we are approaching the future as well. In the past, there was much more serial testing.

Twenty years ago when I first started, the contractor would do something and then throw it over the fence to the government, which would look at it, approve it and then pass it on to the operator.

Now with the pace of technology, and the role of software, we have a much more integrated process. We are shaping the evolution of the aircraft as it goes out the door as well.

At Pax, we are testing a software version ahead or a couple ahead of what the fleet is getting at the moment. In effect, we are testing the next iteration of the aircraft.

And the Edwards and Beaufort efforts provide important pieces to the evolution as well. We have an integrated RAF and Royal Navy team at Edwards. 17 (R) squadron at Edwards is a mix of RAF and RN.

At Beaufort, we have a UK team and one of our aircraft, and we are working closely with the USMC. That is another key element of the joint integrated effort, from our point of view.

See our report on Pax River as well.

The slideshow highlights various images from the Pax River F-35 activities.