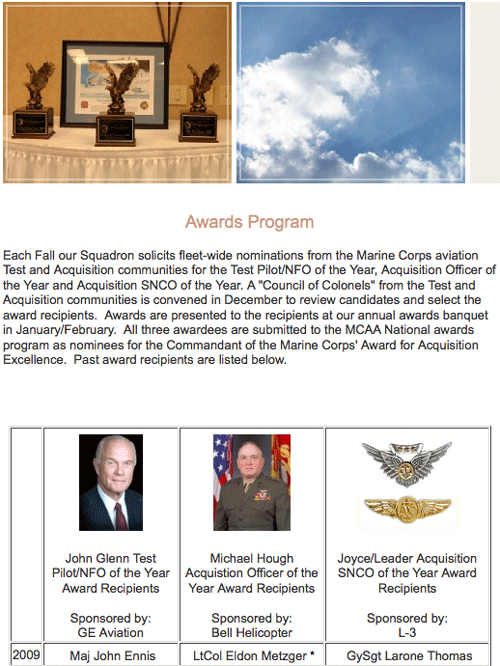

On April 21st, 2010, SLD sat down with Gunnery Sergeant Larone Thomas and discussed F-35 maintenance. Gunnery Sergeant Thomas is in charge of maintenance for the F-35Bs undergoing tests at Pax River and has recently received major recognition from the service for his capabilities in an annual logistics award. he also has significant experience as a F-18 aviation electrician.

Credit photo: Gunnery Sergeant Larone Thomas (left), SLD, April 2010

Credit photo: Gunnery Sergeant Larone Thomas (left), SLD, April 2010

SLD: How is maintaining the F-35 different from traditional aircraft?

Gunnery Sergeant Thomas: The aircraft is the aircraft. Any good maintainer on an aircraft is going to be ready to walk in and be able to do maintenance on this aircraft. There are some new things and there is going to be a learning curve for some, but it’s not going to be so much of a learning curve that is something that we’ve never seen before. If the aircraft does half the things that it is projected to do, it is going to be sweet. It’s going to be ten times better than any aircraft that we have right off the bat.

Based on those capabilities I’ve seen out there on a hover pad and how much thrust and force I witnessed, it will be a major increase in capability. It’s got some very promising things as far as the maintainers are concerned, and as we work on shaping protocols and routines, we can help make decisions for the fleet to make it better to maintain in the field.

SLD: So during the test process you are shaping a protocol process for the maintainers in the fleet?

Gunnery Sergeant Thomas: Correct. Just for example, we had some difficulties based on past practices. You access many things from panels that you would not have on other aircrafts. This takes getting used to. So one day one of the maintainers found some difficulties, but we found that he was not following a procedure appropriate to the aircraft and the maintainer then commented “Oh, you can access it from this door which made it easier than in our past aircraft.” Once you do it, you do it.

This aircraft is tighter and a lot more reliable. It’s chips, the things like that, which are pretty hard to hurt. The package going with you for maintainability is now really shrunken and focused, because the airplane is more maintainable and more solid.

SLD: Can you tell us about your approach to shaping the metrics and protocols for maintenance on the F-35B?

Gunnery Sergeant Thomas: A big change is how we do our maintenance day. On traditional aircraft we have a maintenance checklist and we do a set of tasks each day. Now the day is defined by what the aircraft tells us it needs to have repaired. And we are trying to match our work approach to how the aircraft operates. We’re working to that goal of having an aircraft tell us, “Hey, I’m low on oil.” We have to learn to work with that capability. And this will give us less waste on material as well as not changing on things we don’t need to be changing.

SLD: How about your handheld laptops or Personal Maintenance Aids (PMAs), which are key maintenance tools?

Gunnery Sergeant Thomas: It is pretty much going to allow the maintainer to connect to the aircraft, run up certain systems to verify if the aircraft is in working order and running properly. Right now, the software is not at that state, but in the end game, that’s what we’re working to and that’s what the goal is.

SLD: So the goal is to have the software and the computer being able to dialogue with the aircraft, correct?

Gunnery Sergeant Thomas: Correct. The goal is to have the “maintenance day” defined by what I’m seeing on my screen.

SLD: As opposed to your maintenance day being defined by the checklist.

Gunnery Sergeant Thomas: You’re going to have two separate entities. You have the PMA, which is able to access CMMS, which is Computerized Maintenance Management Tool System, and CMMS is what we document our maintenance on. We use it to document maintenance, order parts and so on, and so forth, but another function for the other PMA will be to run up systems on aircrafts, such as Joint Technical Data (JTD), things of that nature.

SLD: What is the impact of the new maintenance capabilities on operations?

Gunnery Sergeant Thomas: Being able to shorten maintenance time, and the ability to repair the aircraft and generate more sorties in support of the Marine in the field. That is the whole point.

SLD: Unlike the F-18, the F-35 has internal weapons bays. How hard is this to work with?

Gunnery Sergeant Thomas: I’ve loaded this aircraft and I’ve been part of the whole team here, i.e. certified, and it’s not hard at all. It’s not difficult. It’s not going to be a learning curve where it’s going to take extra schooling.

SLD: This is the test regime for maintenance, so presumably it will take longer to do maintenance here than when you have necked down the procedures and do it in the fleet?

Gunnery Sergeant Thomas: Doing pre-flight inspections and post-flight inspections on aircrafts are somewhat cumbersome here, because everything has to be documented. We are shaping a process to getting it down to make sure that there’s not going to be an issue in the fleet. Our inspections are way more involved than what they’re going to be.

———-

*** Posted On July 7th, 2010