2015-03-17 By Robbin Laird

The introduction of new sensors into the supply chain has provided a solid basis for starting to think differently about how to manage the supply chain and the entire logistics custodial system.

As Secretary Wynne underscored in his interview on the start of an industry, the introduction of unique identifiers and RFID tags allowed the beginning of real transparency in the movement of goods for the defense enterprise.

And as Rob Leibrandt from OSD Acquisition, Technology and Logistic underscored, the new sensors then allowed a rethink in how to operate the supply and logistics chains.

As it became possible to match up items with inventories through a scanning device and because of the volumes involved (whether bricks or wheels), “people started to translate this into force management, which was not intended at first. The Defense Logistics Agency (DLA) in particular realized that, if done properly, the right combination of UIDs could make an RFID, allowing you to read up a full pallet load.”

“(…) People started to translate this into force management, which was not intended at first.”

https://sldinfo.com/starting-an-industry-from-uid-to-rfid/

But new standards and new sensors are not enough.

An entire rethink of the workflow and how to then use the operational intelligence generated by the new sensors is required. It is not a question of simply building new file cabinets filed with digital data generated by sensors; it is not simply replacing paper with electronically generated data.

What is facilitated by the introduction of new sensors into the supply and logistics chains is the possibility of a whole new way of working and managing those efforts.

But to turn possibility into reality can not be generated simply by attaching sensors to objects; a new way of thinking and managing data, as well as working with the data generated, including reshaping the relationship between local and central actors is required.

That effort is at the heart of the entire effort of GlobeRanger and the approaches put into practice by the head of GlobeRanger, George Brody and his team. In this series of articles, we will look at the initial approach of Brody, then translated into GlobeRanger’s proprietary software, iMotion, and the diversity of applications to which the software has been applied which in turn lead to the retooling of the software.

This entire effort is unleashing new ways to manage the supply and logistics chains and providing new ways to use automation and work process tools to deliver more accuracy and innovation in supply chain management.

In this article, we will start by looking at the original concept and the origins of that concept by George Brody, which then translated itself into a new start-up company, GlobeRanger.

In the next article, we will look at the software tools and engines developed to implement the approach, iMotion and GR-AWARE.

We will then look at some of the defense related domains to which these tools have been applied and to their potential for a new defense program such as the F-35 global enterprise.

At the heart of the approach has been the application of a telecoms concept and technologies for locating people to forging an approach to shape an Internet of Things. By so doing, an enterprise can locate and monitor goods and supplies in an analogous manner to that of the mobile telecoms approach.

Question: How did your telecoms background affect your initial approach to the world of logistics and shaping what you refer to as the Internet of Things?

Brody: I came at this from my experience in the telecoms world and the shift from landlines to mobile networks. Look at the old landline network. In the global telephone network there was no concept of tracking a person as the person moved around. Calls were directed to some location and jacks in the wall associated with phone numbers assigned to them. The numbers were not associated with a person, but with a place where that person might be found at a particular moment. But the system was not able to find a person in motion.

When people move around they don’t specifically go to a location. They move around. The network had no knowledge of where the person was. So to track a person, the caller had to do a lot of work, the caller had to call you at the office or home. It’s a really dumb network when it comes to tracking of people.

Question: In other words, there was a physical infrastructure to which you were attached rather than the infrastructure supporting the mobile individual?

Brody: Yes. People had to realistically guess where you are, and then start trying to reach you. As a result, call completions were not that good as people were not at the places where they are expected to be.

Voicemail came along so that callers could still get a message to the person he/she was calling. Obviously, this was a stop-gap and transitional means of contact with people on the go.

Question: To be clear, this voicemail system really was based on a series of inboxes. One can put a voicemail into the inbox, but you had no idea where the individual was. So the system was not even focused on people in motion?

Brody: Exactly. I know also the frustration on the part of the caller if you want to get somebody immediately; it was impossible unless you got lucky enough to catch the person in one of the places he/she was likely to be. More than likely, that person was in the car and you could not reach them.

The creation of the mobile network solved this problem.

But to do so, there needed to be a new infrastructure with a different approach tied to a person who is moving around, and the concept of a personal number that is always associated with the person rather than a location.

When that person moves around, the network is going to keep track of where that person is. Interestingly, a network knows where you are. The caller in this case doesn’t have to know anything. They just call your personal number. Then, the network does the rest of the work.

By virtue of this, there is an intelligent network operating where the network adapts itself to the location of the person. Put in other terms, this intelligent mobile network was able to move the process of connecting people away from the fixed wireline network to the edge, namely where the person is in motion.

People can be connected quickly without going back to the old telephone network. That’s what the mobile networks are best at. It’s a very intelligent, smart network at the edge. That’s where I’ve spent most of my telecom career – building intelligent wireless networks. My experience was in the creation of products for those mobile systems which could operate as an intelligent smart, edge network.

Question: Obviously at some point, you began to ask yourself the question, “This is great. This is transformational. It’s revolutionary. What about tracking things?”

How did that happen?

Brody: Just before I started the company, I was on my way to visit my brother’s family in Toledo, Ohio in the middle of winter. Weather was a problem in Chicago and the airline changed connections to get me to Detroit instead. As expected I arrived in Detroit but my bags were nowhere to be found. The airline could track me, but not my bags. The airline software system knew exactly where I was because it was scanning my boarding pass at every gate. Yet my bag was completely disconnected from that system, because the location of the “item in motion” was not (wirelessly) synchronized to the enterprise system.

So I thought to myself: “Here is a problem that is going to be very commonplace.” There are enterprise systems which need to be augmented by an intelligent network to track items that are in motion like baggage or any other things in the supply chain.

So to confirm, I went to warehouses to find out how they kept track of things in the warehouse. Sure enough, it’s a very tedious process. They went from using a clipboard to using a small, little barcode scanner. People were spending a lot of time to keep up with the movement of their items and making sure they end up in the right information system controlling their warehouse or business operations.

The systems were highly manual. They had to make sure a particular item was actually in the warehouse and then sending all the data back into the enterprise system. It’s very cumbersome.

So, the light went on. The enterprise system as expensive as it is, is almost in the same state as what the landline telecom network was prior to the advent of the intelligent mobile network. The items are moving all over the place, closer to the edge. That’s really the edge of the enterprise. The movement is happening at the edge and there needs to be a software layer just like the software layer in the mobile network that can keep track of items in motion.

And that has been my focus of attention from that point on and we built the GlobeRanger approach to be able to keep track of items in motion.

Question: So the IT systems that were operational were virtually clones of paper systems. They were basically digitalized filing cabinets with data pushed back to a central processing center. In other words, they were not attached to the movement of the things themselves?

Brody: People were spending a lot of time trying to keep up with the movement. So that’s why I said “information” about things in motion and items in motion were not synchronized. Having accurate information about things in motion is crucial to any effective management effort.

Question: Your experience in the mobile network gave you the experience of a culture change and a mindset change enabled by the technology. You were looking at how could you map that same capability into the workflow process of the movement of things.

And of course at the same time you’re thinking about this, we have this electronics revolution, which is starting to put in place miniaturization of tags and other sensors that could be tied to your vision.

Is that a fair way to put it?

Brody: It is. Since we are talking in concepts here, you and I are tagged objects by virtue of the mobile phone we carry with us becoming the “tag”. When the phone is with us, when we move the tracking of the location of the phone can be easily associated with our movement. The reason why the “tag” that you and I carry today is big is because it is a full-fledged communication device. If we needed just tracking, the tag could have been much simpler.

In the mobile network there’s only one process that moved from the core to the edge which is the process of making calls or communicating with others.

In managing the movement of things, we are focused on many processes and the key question of which processes are better handled at the edge and what needs to go back to a central processing center.

By focusing on the workflows, one can determine what data does not need to go back to the core anymore. We can do workflows at the edge. Once the edge network is in place, you can move some of those processes and workflows to the edge.

Question: In effect what you’re saying is a parallel transformation to what happened to phone communications. You’re putting yourself in a situation where everything doesn’t have to go back to the hub.

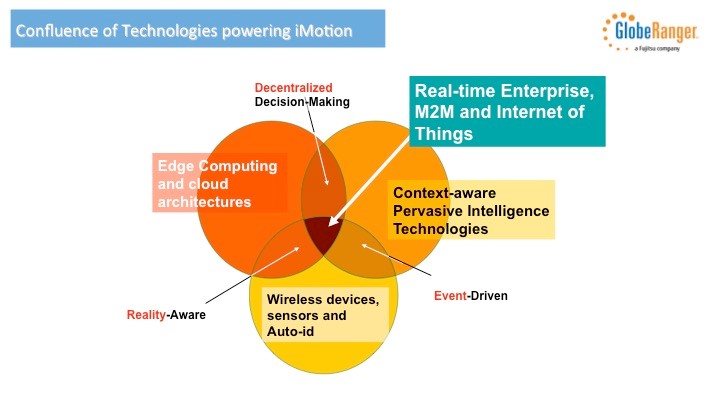

In effect, you are discussing the confluence of several processes, which need to be mastered to deliver the kind of transformation of management of supply, and logistic systems, which you have in mind.

In looking through your background material, which I read through for this interview, there is one slide which highlights the confluence of processes, and seems central to your approach.

What this graphic illustrates is that decision-making and the flows appropriate to the level of decision making is a key challenge and requirement for effective logistical operations.

And your system is technologically agnostic in the sense that the sensors can change, now RFID is crucial but this could change, and your focus is on managing information on the edge and helping informing decision about decision making and work flows.

Could you talk to this graphic and explain the thinking behind it?

Brody: The part that you picked out of the text represented the confluence part is very fundamental to our thinking and to our approach.

The confluence of Edge Computing, Wireless Sensors and Context-Aware technologies is causing reality awareness, events and decentralized decision making at their respective intersections as shown.

Let’s look at it together. I have with me a tag or sensor attached to an item. I want to know what is actually happening in reality. What is really happening?

In order to do that I need to have this little sensor out there and then I need to have some kind of edge computing that needs to be done closer to where the sensor is. At the intersection, that operational reality is yielded by the intersection of edge computing, and the sensor device.

We also need to have events. There are certain things that are happening which require correlation of sensor data to create an event.

For example, I now have a situation where the temperature of an item has exceeded beyond the allowed limit. There is a temperature reading, and then there is threshold beyond which we have an alarm situation.

That is context awareness. So that will create an event saying that there is an exception situation and the temperature of the perishable item has exceeded for five minutes and it is no longer usable. The intersection between the context-aware technology and the sensor data gives me that valuable event.

When I take the intersection of edge computing and the context awareness together with the events and the reality, I can now establish business rules and make a decentralized decision based on correlating the proper information with the proper business rule.

A key part of the approach is helping determine which events should be handled locally, which events should be driven to some other management level, so you’re actually building a kind of a hierarchy, a network of decision-making. You’re trying to understand what is better handled locally, rather than choking the system and being sent back to the core.

In this new approach, decisions can be made locally. Previous architectures didn’t allow us to determine the correlation between reality information, business rules and events to enable decentralized decision making.

We are building a smart network that has a picture of how the data goes from edge to the core.

Previous systems would have sent data back without any filtering to the enterprise system and what is this going to do.

There has to be a certain level of filtering and aggregation built into the physical level of the edge network. But then once you got the data all filtered at the physical level, then correlation of multiple sensor data, in manufacturing an event using the context information, business rules can be applied and decisions can be made.

Question: Correlation is the key to this approach and thereby putting appropriate decisions to the edge, and enabling more effective decisions at the core?

Brody: Exactly, correlation allows us to create something meaningful. The fact that things are moving is given but what does it mean in the context of the supply or logistics chain?

Question: Essentially you’re creating operational intelligence and shaping an understanding of a work process that actually could allow you to master the supply chain

In effect, your approach is about generating meaningful operational intelligence about the movement of things in a supply or logistics chain?

Brody: That is clearly an outcome of the approach. To move from simply having data about the movement of things, we are providing ways to manage the supply chain more effectively.

And the edge computing approach is designed to ensure that data is handled appropriately at the local area and not sent flooding the core, putting major bandwidth and noise distortions into the management system.

Question: Let me ask you a final question.

Obviously, RFID technology is a key enabler for your software systems and approaches, but hardware will change, and it appears you are hardware agnostic.

So when new sensor technologies arrive, your sensor agnostic approach can kick in effectively?

Brody: This Venn diagram we have been discussing assumes that the world is going to be changing so rapidly and hardware is going to change significantly over time. I don’t want to be tied to it specific piece of hardware, so we built this in a way that the top two circles are independent of that bottom circle which is the hardware being used currently by the logistics system.

It has to be one of the fundamental principles of building this edge platform. There can be all kinds of sensors, all kinds of things wired, wireless, it doesn’t matter to the approach which we have built and are applying in a diversity of industrial supply chains.

For the first piece in this series see the following:

https://sldinfo.com/managing-defense-supply-chains-shaping-a-21st-century-way-ahead/

And for a GlobeRanger white paper on smart networks:

https://sldinfo.com/whitepapers/supply-chain-management-innovation-building-smart-networks/