2015-04-22 By Robbin Laird

During my recent visit to the United Kingdom to visit the new large deck carrier, the HMS Queen Elizabeth, I met with Tim Gibson and Eric Bownes of Fujitsu defense, both based in the United Kingdom, and discussed the evolving approach.

In the interview with Tim Gibson, the Vice President of Defense and National Security in Fujitsu UK, described the evolving approach of Fujitsu in addressing shape global solutions for logistics for a number of key militaries in allied states.

As Gibson highlighted the opportunity and the challenge:

The change in Japan with regard to defense highlights the opportunity to take our work and merge it more generally with the company in shaping a global business. Fujitsu in Japan has built up a large defense business, and we’ve now seen synergies between all our different elements of our business. In the 26 countries Fujitsu operates in, there are either developed, in three of them our core defense business.

But these businesses have been built as silos; the challenge is cross operate and to shape global integrated solutions.

Everyone’s defense budgets are under pressure. Everybody’s looking at standardizing, and we’re suddenly seeing a market, we think, where the interoperability between countries on common platforms means they will want sort of common support models and common infrastructures and on a global basis.

For us that’s a convenient piece of timing about where we were thinking about how we would try to build a more globalized defense business and take best of breed solutions, whether that’s from Japan, or Australia, or the US or the UK, and apply those business solutions in a consistent way across all the countries we operate in.

In this interview with Eric Bownes, the longtime logistician, focused on a number of the key ways to make more global solutions in logistics a reality.

Currently, Bownes is working the Global Defense Initiative for Fujitsu and his formal title is Director, Solutions and Strategy, Fujitsu Global Defence, Defence and National Security, Fujitsu, UK.

As one might guess, although based in the UK, he is a frequent visitor throughout Europe, Asia, Australia and North America.

His background as a military logistician was with the South African Air Force, where he worked for 22 years in various capacities in military logistics operations. After leaving service in the South African Air Force, he joined IBM in the UK and worked on the implementation of the implementation of the RAF’s logistic information system, a system still used today by the RAF. Seven years ago he joined Fujitsu and has been part of the growing logistics business.

“When Tim took leadership of the business four years ago, we started looking at the globalization of our portfolio solutions to go into more global market, based on what we were doing between the UK.

The UK was already semi-global because we had some of our solutions going into Europe, notably into the Netherlands and Portugal.

We were already operating multi-nationally in terms of not only selling to UK MOD but also into Europe.

We’ve also done significant collaboration with Australia, as Australia is part of what is called the Five Eyes community.

They took our networking concept developed in the UK and implemented that in the Australian defense force.

And as Japan, in 2011, started signing up to the F-35 Program, they realized that we needed to form what we call today a “Global Defense Initiative” in order to bring together the best of breed out of the three nations, (Japan, UK and Australia) and how we can take that collectively to a global market.

Also we needed to address the American markets, for we had no presence at all in terms of selling to either MODs or DODs, in those regions, across the Americas and also with the major defense primes there as well.”

Question: The GDI was born in part by the Japanese decision to join the F-35 global enterprise and the reality that being a supplier to the F-35 meant that you were a global, not simply a national supplier.

Could you elaborate on that aspect of the standup of GDI?

Bownes: The initiative was born out of Japan’s thinking. When the government decided to join the F-35 program, this meant involvement in the global supply chain. This in turn meant opening up other global supply chain opportunities as well.

Of course the UK and Australia signed up to be partners for a long time before Japan signed up to the F-35 Program. The Japanese leadership of Fujitsu realized they needed the input from us, and we are working with them to shape the GDI.

I think they also realized that we’re talking about other multinational programs, such as the A400M or the C-17s, means that one needs to have an organization with global defense presence in the relevant regions around the world.

Question: And I assume that in your work in the UK you were coming to terms with the impact of multi-national programs as well relevant to the shift in Japanese thinking?

Bownes: I was. When I was with IBM in my previous role, one of the functions I did have was as trusted client advisor. I was actually part of the team that was working with the then Joint Combat Aircraft Team advising them on how do they bring in systems like ALIS and looking at the potential for leadership within that program.

I was working within the DOD, providing them advice on terms of future programs around A400M and the F-35 and the Eurofighter Program, in terms of how do you bring in systems that can help the customer shape interfaces with the suppliers and the original equipment manufacturers to deliver more effective logistical solutions?

Question: And presumably you were working software interfaces with security built in rather than focusing on hardware solutions, which really make integration difficult?

Bownes: That was and is our approach.

It is not necessary to rip up the investments made in separate systems in order to achieve integration; you can do this by building software translators, rather than proprietary and costly hardware systems.

What you’re looking for is the ability to build smart networks and applications that actually fuse data coming from separate systems into information.

The task is to shape smart networks that will bring information to the front so that you can translate all that data into meaningful information to decision makers right at the edge at the working level and push only that information needed at the senior level as appropriate.

Question: In effect, with smart networks you are looking at translators among subsystems to shape manageable decision-making systems or IT enablers that are really decision making rules and systems that is one of the key focus of your efforts?

Bownes: That is essentially correct. We are focused on shaping a network with the right type of fusion and integration technology and then coming up with smart user interfaces that present information to the users in decision-making format.

When we look at something like the ALIS system for the F-35, it is easy to misunderstand what it is and isn’t intended to do.

What it is intended to do is to provide the information for platform sustainment and through live management and to do so by transparency in the parts supply and life performance system.

It is not designed to replace an MoD’s entire logistical systems.

One can use smart networking technologies and integration technologies to integrate ALIS with any other system, be it to national ammunition or explosive ordnance systems or to HR systems.

Each country will be unique without having to go and redevelop or try and embed too much of their technology in ALIS.

What needs to be avoided are relying on hardware interfaces for that will just drive up the cost of the whole sustainment program, which is what you don’t wan. And through life costs which are still going to be 90% of the total platform cost of F-35s (as with other systems) over the next 30 to 50 years.

Question: So a way to look at ALIS as somewhat like a global spiderweb which intersects with a country’s own IT networks to sustain other aspects, or operate other aspects of the force.

By building smart networks you are intersecting the ALIS global spider web with the country’s own defense logistics networks.

You’re not asking ALIS to replace everything or everybody to be ALIS-ized, is that correct?

Bownes: Absolutely. I think what you don’t want nations to do is to start doing hard interfaces to their backend warehouse systems because in the true performance-based logistic context of ALIS, those items will be delivered by the primes,

Lockheed Martin and Pratt & Whitney, directly to the bases or the carriers where they can operate.

Why does it have to go into warehouse systems? If you do so then you lose the total key measurements around the performance-based logistics system whereby you can measure performance and deliver effectiveness to deployed forces.

Question: So you see the F-35 sustainment approach as an input to logistics transformation?

Eric: Absolutely. And we see cloud computing, where Fujitsu is a world leader in secure cloud computing, as a key part of the global solution.

We see cloud as being part of the solution.

I think what still has to be agreed by the relevant end-user customers, your DODs and MODs around the world, and the prime contractors is whether it’s going to be a private Cloud for certain systems.

When you take a look at the F-35 environment, one of the big issues that’s going to come into play is the whole potential about parts counterfeiting, given you’ve got nine partner countries all having work shares and making parts.

How do you control the total supply chain and reduce the threat from counterfeit parts?

We could use a collaborative cloud, but it could be a secure collaborative cloud just for that community in terms of managing the full supply and support chain, in terms of moving assets around and knowing that there are not counterfeit assets within that supply chain.

Question: What is the impact and advantage of Cloud computing for this kind of global IT approach to logistics support?

Bownes: If we take the case of Europe, we can look beyond the classic warehousing and stockpiling systems. You can shape regional solutions that historically were done through national stockpiling solution approaches.

The regional system can provide parts and the complete history of those parts to the nation needing that particular part.

And the information can be embedded in the part not just the global system, so that when that system is down or disrupted, there is still asset visibility available to the customer.

Question: In effect, what is envisaged is delivering the level of integration seen operationally but now within logistics, which has been largely stovepiped?

Bownes: Integration has been seen at higher levels of defense establishments than down to the level of logistics. Stove piping remains the order of the day despite modern IT technologies.

You’ll find is systems have evolved in silos around the people’s different mastery, so logisticians have systems for logisticians; there are systems for engineers and then systems for operating the forces.

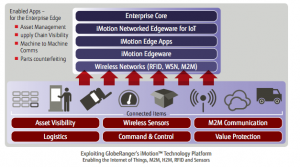

Question: Fujitsu bought GlobeRanger clearly to have a US footprint, given the GDI. But clearly, you were looking for a company that could contribute to the smart networks efforts you see as fundamental to logistics transformation.

How do you see the GlobeRanger acquisition within the broader Fujitsu scheme of things?

Bownes: We were looking for the capability, an underpinning capability, that can take data from sensors, can fuse and bring that data into the information so a single scanning in of the goods in process, be it through a barcode or an RFID, informs all the systems and the people in that relevant enterprise at the operational level what is happening.

Over the last 20 years, DODs and companies have been bar-coding, doing RFID, bringing in these new technologies, but they’re just not integrated with a single system informing the multiple processes.

As people implement SAP or Oracle enterprise systems, they still implement them in silos.

The processes aren’t integrated and they don’t inform other systems. MODs have multiple systems for logistics in terms of inventory management and then MRO, but people aren’t getting the view of what’s happening and where things are in terms which would allow them to make an informed decision.

For example, even when something has arrived at my hangar assigned to aircraft A, it could be that same part could be needed by aircraft in bay C. Just the ordering process with an MRO doesn’t inform the supervisor that he can actually move that spare and gain an aircraft on the flight line immediately because it will go to the bay where it was ordered for.

It’s the way the process has worked, and we can overcome that with bridging technology.

We saw that GlobeRanger had the capability to do that, but the big challenge now that we face having acquired and integrated is to get them and their current customer base and our future customer base to think in terms of visibility providing decision-making capabilities at all levels of the enterprise.

We see GlobeRanger as a stepping stone into the broader Americas market, but again we’ve got to change that market because that market is still very siloed in its logistics approach and we can broaden that and that is a core capability which GlobeRanger with Fujitsu IT solutions can bring to the global customer base.

Note: The Fujitsu Global Defence Initiative Fact Sheet can be downloaded below:

Fujitsu Global Defense Initiative

According to the Fact Sheet:

Fujitsu’s Global Defence Initiative (GDI) has two strands.

Firstly, the GDI aims to harness the capabilities, technologies and products from the global Fujitsu catalogues which are defence related or have defence applications, and take them to market as appropriate for the rest of the world.

Secondly, the GDI has a global remit to lead Fujitsu’s presence as a Global Defence provider of services and capability, in the multi- national Defence domain. GDI will allow Fujitsu to deliver directly and to assist Defence Vendors / Original Equipment Manufacturers to deliver cost effective solutions to their customers.