2016-07-09 After an extensive competition, the Australian government downselected the French firm DCNS to build a new class of advanced conventional submarines.

In a press release from the Australian government dated April 26, 206, the Australian government announced the decision and underscored that

“The decision was driven by DCNS’s ability to best meet all of the Australian Government’s requirements.

These included superior sensor performance and stealth characteristics, as well as range and endurance similar to the Collins Class submarine.

The Government’s considerations also included cost, schedule, program execution, through-life support and Australian industry involvement.”

Less obvious in the press coverage around the decision was the innovative nature of the program and the significant opportunity to leverage evolving technologies in shaping the largest conventional submarine, which DCNS has been involved in building.

In many ways, it is a “hybrid” submarine in the sense that it leverages the innovative technologies of the new Barracuda SSN being put to sea next year by the French Navy, leveraging the extensive experience which DCNS has in building the Scorpene ion class submarines in Chile, Malaysia, Brazil and India, and, for the first time, operating with a US combat system which will be shaped for this conventional submarine operating at range, speed and distance in the challenging waters of the Pacific.

In an article published by the Australian publication Manufacturers’ Monthly on July 4, 2016, the perspective of Chris Burns, then CEO of the Defence Teaming Centre in Australia highlighted the approach to building submarines in Australia.

Regularly referred to as the second-most difficult thing to build after a space shuttle, the ability for a country to build its own submarines is a measure of industrial sophistication, a critical bit of sovereignty and more besides.

“If you can build a submarine you can pretty well build anything,” Chris Burns, then-CEO of the Defence Teaming Centre, told Manufacturers’ Monthly recently…..

The decision to base the submarine build at Adelaide was the right one, believes the Teaming Centre.

The ASC workforce has 2,600 skilled tradespeople and engineers, as well as the existing infrastructure. A new factory, “a bit larger than the Adelaide cricket ground” must be built to make the new subs, according to DCNS.

Nothing against Western Australia; they are fully capable of doing the middle-level maintenance,” said Burns of the shipbuilding rival state.

“What they don’t have is that experience – for example, here in South Australia we can physically cut a hole in the submarine or cut the submarine in half in order to refit it.”

Shipbuilding projects such as the Future Submarines and Offshore Patrol Vessels are hugely important to the state’s industrial strength. It is losing production at Holden’s Elizabeth plant next year and the future of the Arrium Whyalla steelworks is not certain.

The state has only 8 per cent of Australia’s population, but about 25 per cent its defence industry.

SA’s DTC has long campaigned for a continuous shipbuilding program to level out peaks and troughs in work and consistency for the shipbuilding workforce.

A claimed premium of 30 per cent to build submarines here was sometimes cited by critics of the DCNS contract.

Burns said this is unfair, and the local naval defence industry hasn’t had the chance – due to the stop/start nature of contracts in the past – to build up its muscle tissue.

“With the Air Warfare Destroyers from ship one to ship two you had a 30 per cent productivity improvement and from ship two to ship three we’ll have a 20 per cent improvement in productivity,” said Burns.

“And that’s consistent with when we built the Anzac frigates, when we built them from scratch as well. Once you get the drumbeat going and the workforce aligned and productive, then you are globally competitive and there is no premium to pay.”

Any premium is also more than negated by things such as investing in the local industry, taxes being paid and not having to pay welfare to workers between jobs, he added…..

And in a piece written by Trevor Thomas on the Australian Defence Business Review at the time of the announcement of the decision by the Australian government, the analyst highlighted a number of key aspects of the decision.

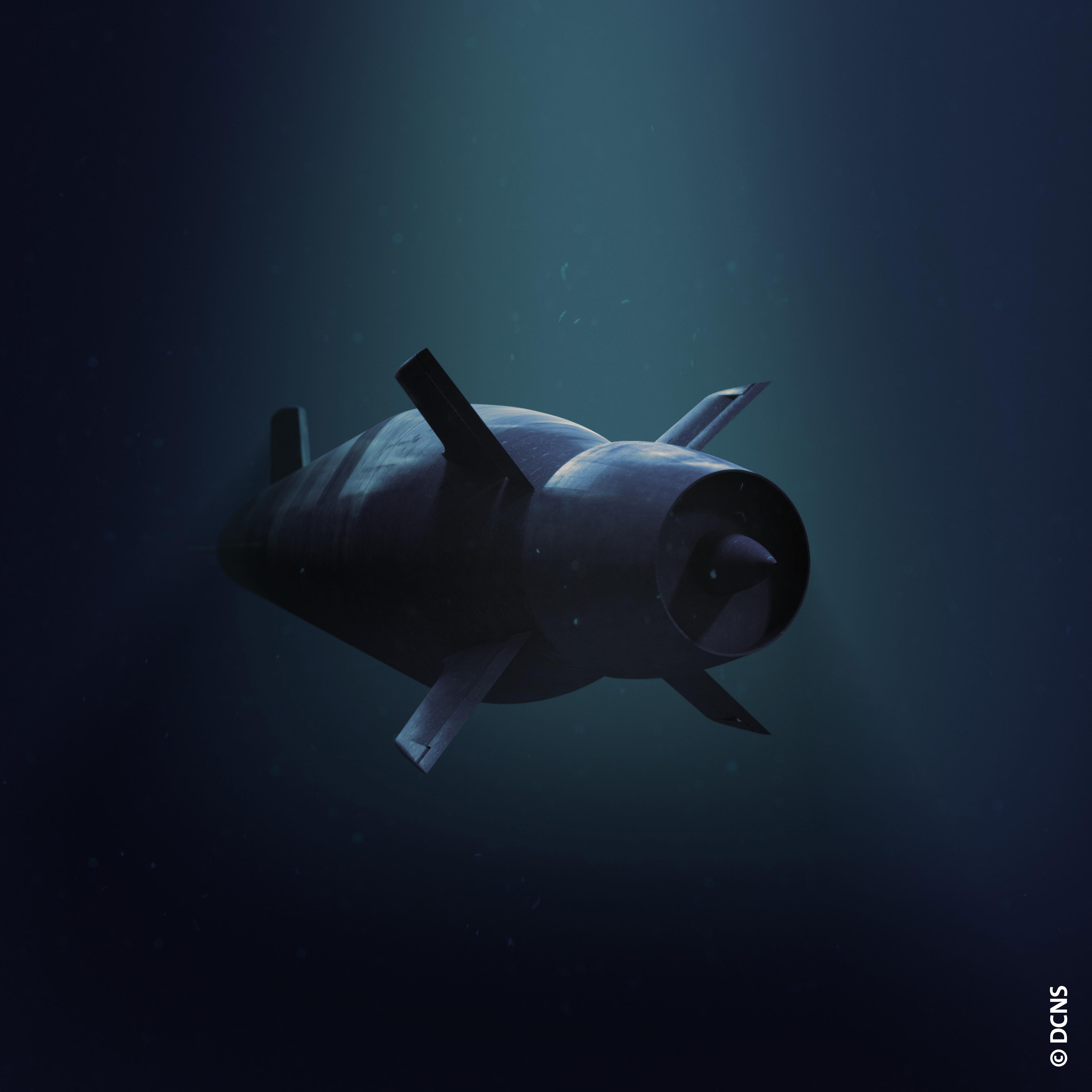

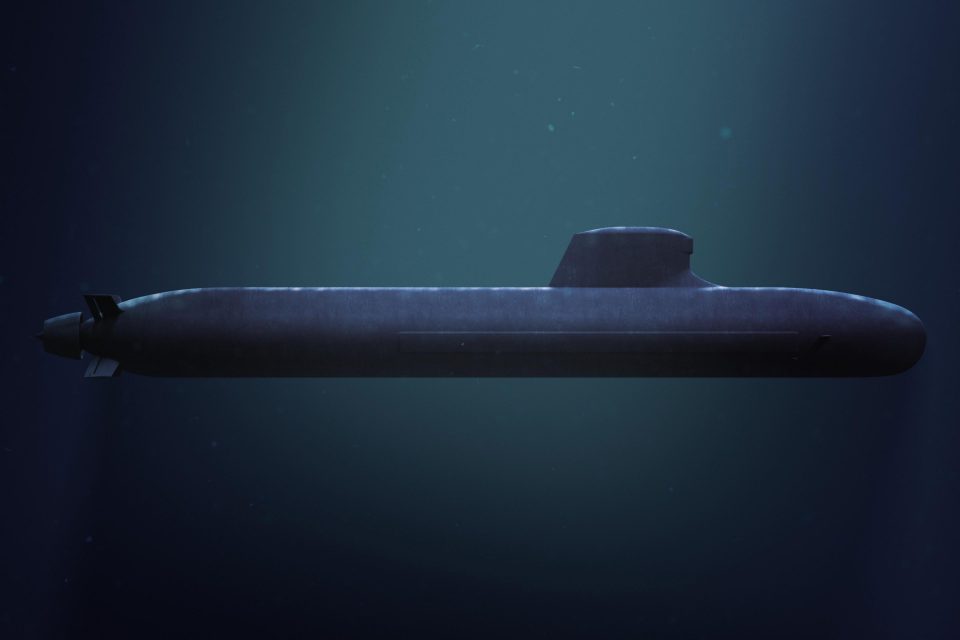

The 4,500 tonne Shortfin Barracuda design represents the embodiment of all of France’s knowledge of both nuclear-powered and conventionally-powered submarines into a mature large platform design, whose first-of-class nuclear-powered Suffren is already well down the construction track for a launch in 2017.

Overall design and construction risk for Australia’s boat has therefore been substantially addressed, other than the switch to conventional power for which French shipbuilder DCNS has previous experience to draw upon…..

France offered Australia a more contemporary submarine design that will be the recipient of its most sensitive and protected submarine technology, and therefore likely to yield the most lethal conventional submarine ever contemplated by Western nations. To that has also been promised a distillation of technology from France’s nuclear submarine program – including technologies such as pump jet propulsion –something that neither Germany or Japan were in a position to match.

Rather than the progressive iteration of historical conventional submarine designs for export – as in the case of the Germans, and the updating of an older submarine design drawing more on strategic considerations for attraction than real differential capability – as in the case of the Japanese, France has offered Australia a bi-national industrial collaboration that brings with it the transfer of all technology, know-how and resources necessary to achieve operational autonomy and sovereignty in a regionally superior platform that also satisfies local requirements for interoperability with major allies.

Added to the French package is intimate government involvement (and therefore assurance) in the Future Submarine project, not just through majority ownership of DCNS, but also via a detailed technology sharing and industrial cooperation agreement from the French Director General of Armaments (DGA) attached to the original CEP response.

All these industrial undertakings were next cleverly integrated with the Australian Government’s National Innovation and Science Agenda to ensure sovereign capabilities will be put into place to support the new submarines over their full life cycle.

DCNS was also quick to pick up on the subtle shift of terminology in the new Defence White Paper from a ‘continuous build’ of surface ships, to a ‘rolling build’ for Future Submarines.

The White Paper’s introduction of a breathing space – by way of a review in the late-2020s to assess whether the Future Submarine’s configuration remained relevant to contemporary strategic circumstances facing Australia – also saw DCNS proposing successive Block 1B capability developments, and including a latter Block 2A development that could possibly see a reversion to nuclear-powering of the boats should strategic developments and local Australian politics consider that necessary…..

Twelve new submarines of the Shortfin Barracuda genre will make a major contribution to the combined military deterrence of the US, Japan, Australia and other allies in the Asia-Pacific region. Interoperability is assured through the Government’s mandating of a US combat system.

France is nevertheless unique among European countries in terms of retaining specific responsibilities regarding defence and security in the Asia-Pacific subject to its holding of territories extending across New Caledonia, French Polynesia, and the Wallis and Futuna islands. More importantly, alongside the US, France and Australia are the largest contributors to the fight against Islamic State in Iraq and Syria.

Australian warships are regular contributors to coalition operations in the Middle East, and recently a Navy frigate undertook joint exercises with a French Navy Task Force in Middle East waters, while RAAF KC-30A tankers have regularly been employed to refuel aircraft operating in that area off the French nuclear aircraft carrier, the Charles de Gaulle.

Selection of the Shortfin Barracuda and DCNS of France as the preferred design/builder for Australia’s future submarines is a pragmatic choice by the Australian Government, which promises to bring the nation long-term benefits via combining the best of contemporary underwater warfare capability and industrial collaboration opportunities to enhance the long-term economic and national security of Australia.

The Australian MoD is very interested in shaping cross-cutting convergence among the services as the transformation of the force is shaped.

With regard to submarines, there is a clear interest that the submarine can leverage the extensive air modernization strategy being put in place by the RAAF, which means that DCNS and the winning American provider for the combat system can partner with the overall transformation of the Australian forces.

The artist drawings in the slideshow and the video are credited to DCNS.