By Robbin Laird

The Australian Offshore Patrol Vessel or the Arafura Class OPV program is the launch program for the new Australian approach to shipbuilding.

Termed a “continuous shipbuilding process,” the core point is to have an ongoing shipbuilding effort, rather than a start and stop approach built around a single platform naval acquisition, one at a time.

But the new approach is more than that. It is about shaping a new industrial-government partnership and having a new role for the lead contractor working with Australian suppliers.

This article is the first of three.

I have had the chance to visit the Henderson shipyards, and an opportunity to talk with Luerssen and CIVMEC, the two partners in the Australian Maritime Shipbuilding and Export Group (AMSEG).

In a May 26, 2018 press release, Luerssen provided an update on their partnership with CIVMEC:

One of the world’s leading shipbuilders, Luerssen, has teamed with Australian engineering and construction firm Civmec to create a new force in naval shipbuilding and exports.

The joint venture, Australian Maritime Shipbuilding & Export Group (AMSEG), will partner Luerssen Australia, the prime contractor and designer for the Australian Government’s Offshore Patrol Vessel program, with West Australian-based Civmec, soon to list on the Australian Stock Exchange.

It is intended that AMSEG will play a significant role in the build of ten OPVs in Henderson, Western Australia and in driving an export shipbuilding business that will target opportunities around the region.

The joint venture will be chaired by one of the nation’s foremost naval experts, former Chief of the Navy, Vice Admiral (ret) Chris Ritchie.

“This new company will be governed by an Australian board and operate under Australian management to build world class naval vessels in best practice Australian shipyards,” Vice Admiral (ret) Ritchie said.

“We will invest in Australian skills and infrastructure and transfer expertise from SEA1180 prime, Luerssen Australia, to develop capability and support the foundation of a sustainable naval shipbuilding industry that is able to export to the global market.”

Executive Chairman of Civmec and AMSEG Director, Jim Fitzgerald, said the formation of the new company was further evidence of the commitment the SEA1180 industrial team had made to materially growing Australia’s shipbuilding industry.

“This is a huge step forward for Australia’s shipbuilding industry. It is an exciting development that will fully underpin the development of the new state of the art shipbuilding facility at Civmec’s Henderson headquarters,” Mr Fitzgerald said.

Mr Fitzgerald’s comments were echoed by Tim Wagner, Managing Director of Luerssen Defence and AMSEG Director.

“Luerssen has always believed in the vision of the Australian Government’s Naval Shipbuilding Plan and wanted to not only be a part of it, but to help make it a reality.”

“We set up Luerssen Australia in May 2017, today we have announced this important joint venture and later this year we will open applications to our program which will fund scholarships and apprenticeships for aspiring Australian shipbuilders. The future of Australian naval shipbuilding looks bright,” Mr. Wagner said.

In this article, the focus of attention is upon Luerssen; the next article on CIVMEC; and the third on the OPV team for the Commonwealth of Australia.

With regard to the partnership, Luerssen Australia Pty Ltd is the prime contractor with the Commonwealth and CIVMEC is its WA based ship building partner. The AMSEG JV is focused in the short to medium term on sustainment activities and future builds outside of SEA1180.

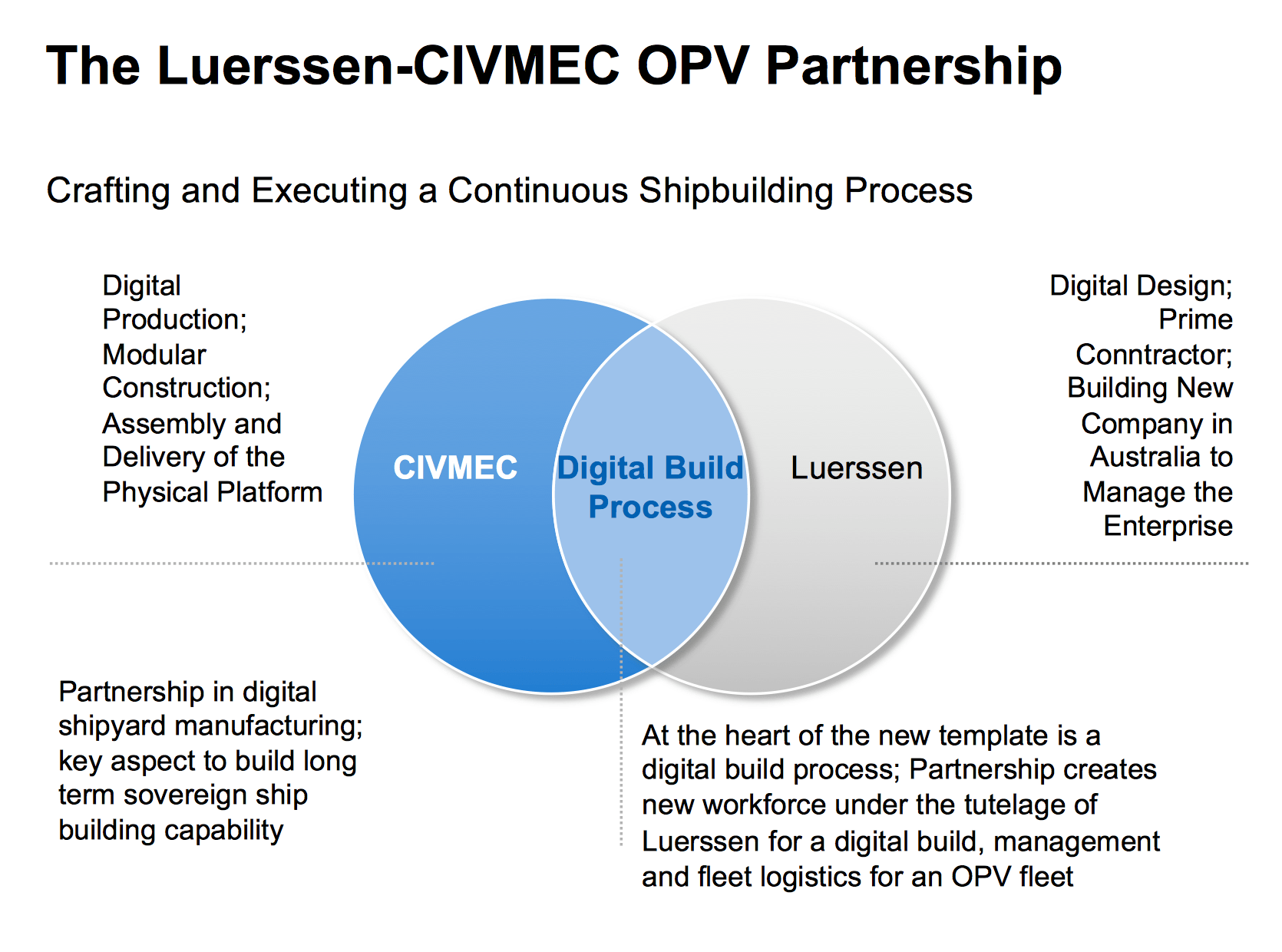

In the graphic below, I have conceptualized how one might look at the partnership between Luerssen and CIVMEC and the roles and interactive relationship between the two partners. This working relationship is clearly a partnership, a point which was emphasized throughout my visit to Henderson. It was highlighted as a collaborative, close, mutually shared objectives partnering approach for the partners.

During my visit to Luerssen at the Henderson Shipyard, I had a chance to meet with Enrico Kestel, SEA1180 (OPV) Training Manager and Mick Handcock, SEA1180 (OPV) Senior ILS engineer.

While I am not going to quote them directly, I will highlight takeaways I had from our conversation, my visits in Perth and Canberra, and my review of public statements, press releases and articles by other analysts of the program.

The first key takeaway is that the major challenge facing Luerssen is that it is both responsible for delivering the program to the Commonwealth and is also engaged in setting up a company in Australia.

Lürssen is an integrated shipyard in Bremen, Germany with habitual working relationships with their suppliers; in Australia, Luerssen is taking the Germany expertise in design and build and applying it to Australia but working with a new group of suppliers to shape the new build process in Australia.

The second key takeaway is that it is a new build process.

It is a digital design and build process.

The design is worked in Bremen, reviewed and confirmed by Luerssen Australia at the build site which for the first two OPV’s is being done at the BAE/ASC Adelaide yard at Osborne.

When I visited the CIVMEC facilities in Henderson, one could see the digital process in operation, where the robots under the supervision of the CIVMEC team were translating design to production.

A key advantage of this process is that the production process clearly identifies where the parts being fabricated have come from, up to and including the suppliers.

This leads to a significant quality increase as there is significant transparency through the digital build process.

In fact, Vice Admiral (Retired) Tim Barrett underscored the importance of the new process for the shipbuilding approach being put in place:

“The Luerssen -CIVMEC partnership is meant to create a new workforce under the tutelage of Luerssen (particularly in manufacturing in digital shipyards) rather than merely compete for an existing (pre-digital) workforce.

“This is an important feature in a long-term sovereign ship building capability.”

The third takeaway is that an ongoing dialogue between Luerssen and the team in the Department of Defence working OPV is absolutely crucial to the effort.

And in Bremen, there are members of the Australian OPV team as well working directly with the design side of the build process.

It is clearly crucial to align expectations on the project for both industry and the government, and the team talks multiple times daily with regard to the ongoing effort.

In my words, what is crucial for success with the new approach is “expectation management,” rather than having a requirements list operating as a sledgehammer by government to gain industry compliance.

It is a very different process if one wants to build a ship which is delivering capabilities for a concept of operations; rather than building a platform to a narrow set of pre-set requirements.

The fourth takeaway is that for the Germany company, it is operating in Germany with an Industry 4.0 process which is how the digital build and sustainment process is then realized.

For this to work effectively, all of the suppliers as well as Lürssen must have the proper data flowing through the system to ensure the kind of accuracy and predictability of the build understood as a workflow process.

A challenge in Australia will be for Luerssen Australia and the Commonwealth to have a supply chain that can operate at Industry 4.0 standards and provide the flow of the quality and reliability of the data required to shape an effective build process flowing into the integrated logistics process as well.

This clearly is a work in progress.

For the launch of the contract, the Commonwealth mandated a set of key suppliers, but in managing these suppliers and adding other Australian SMEs, Luerssen works a proposal to the Commonwealth with regard to vendors and terms of working with the vendors, and the Commonwealth then makes a decision for Luerssen to implement.

The tender for the Capability Life Cycle Manager (CLCM) role within what is termed the OPV Enterprise, essentially the combined Government and industry “sustainment team”, has just been released. An industry day was scheduled to be held on March 16, 2020 but was postponed due to the coronavirus impact.

But given the nature of the very different build process, it is clear that the approach to logistics will be shaped differently as well from a legacy shipbuilding process.

A key aspect of the ILS solution set will be to craft a fleet wide logistics solution for the OPV over the full Life of Type (LOT) up to and including disposal of the fleet.

How this will be done is a work in progress, and a significant aspect of the program going forward, but clearly, getting the work process data flow right in the build process will facilitate getting the work process data flow for sustainability right as well.

And that is a key part of the new approach associated with “continuous shipbuilding.”

It is not just about a build; it is about having a sustainable fleet built around a digitally upgradeable ship.

In a later article, I will address the configurability and modular aspect of the ship and why from the Navy’s perspective the design offered by Lürssen provided the kind of flexible space and power necessary for the projected future for the ship.

Appendix: The Key Suppliers on the Offshore Patrol Vessel Project

The above table comes from the SEA 1180 Phase 1 Offshore Patrol Vessel Public Plan published in October 2018.

This document added the following as well:

Luerssen Australia Pty Ltd, an exciting new entrant to the Australian defence industry landscape, is contracted by the Commonwealth of Australia (Commonwealth) as the Prime Contractor responsible for building 12 Offshore Patrol Vessels for the RAN. Construction will start in November 2018 and is expected to be completed around 2029/2030.

Luerssen is a subsidiary of a long established and successful shipbuilding group in Germany and it will quickly build its capabilities and staff in both Adelaide, SA, and Henderson, WA, to establish fully operational program management, support and engineering design capability. Luerssen has selected as its shipbuilding sub-contractors two key industry players which will offer maximum Australian involvement:

ASC OPV Shipbuilder Pty Ltd which will build the first 2 OPVs in Osborne, South Australia, and Civmec Construction & Engineering Pty Ltd, located in Henderson, Western Australia, where they will build the next 10 OPVs.

The current total contract value (until 2030) is $1,988 million expressed in constant year dollars exclusive of GST or $2,570 million expressed in out-turned year dollars exclusive of GST.

The portion representing Australian contract expenditure is currently estimated (prior to all sub-contracts being finalised) at $1,220 million in constant year dollars exclusive of GST. The AIC value has potential to grow as the program proceeds including opportunities to increase Australian industry participation linked with design reviews at ships 3, 6 and 9.

Luerssen has contracted with the major subcontractors identified in the table below to manage the majority of construction and supply activities associated with the program.

In addition to these shipbuilders Luerssen will directly engage a number of Australian companies including many Small to Medium Enterprises (SMEs) to perform work under the contract. The scope of work to be performed by these companies includes manufacturing, logistics, engineering services, project management, supply of specialist equipment items and provision of contract labour supporting contract deliverable activities.

According to a lead in by WA DEFENCE REVIEW to a video interview they did in 2018 with Peter Lürssen:

As a leading global shipbuilder, the Lurssen Group has successfully entered the Australian market, and is now heavily invested in the build program for the Royal Australian Navy’s offshore patrol vessel.

In late October Lurssen Group CEO, Peter Lurssen, gave an exclusive interview to WA DEFENCE REVIEW and talked about the company’s current activities and future interests in Australia and neighbouring regions.