In an interview with Colonel Turlip of the USMC in mid-2007, the nature and status of the USMC logistics modernization effort was discussed. Colonel Doug Turlip at the time was head of the Logistics Vision and Strategy Center (LPV) within the Logistics and Installations Division of Headquarters USMC. Colonel Turlip’s most recent combat experience was as a logistics officer in 2003 in Operation Iraqi Freedom (OIF). In addition to his significant combat experience, Col. Turlip has advanced degrees in Business Administration, including an Advanced Certificate, Logistics and Technology, Kenan-Flagler Business School, The University of North Carolina at Chapel Hill, 2006

Col. Turlip and his staff indicated that the LOGMOD effort was entering a key phase. The modernization effort languished before the military operations in Afghanistan and Iraq. With the pressure of war, logistics modernization became elevated as a concern. The modernization effort has gained new prominence in USMC operations. But much remains to be done. A major restructuring is underway and will be tested in simulations and field testing this year. A systems partner has been selected to work with the USMC in designing and executing the new strategy. In other words, the USMC is getting serious about logistics modernization and is launching a multi-faceted reform effort under the pressures of war.

At a very top level, Col. Turlip underscored two key dynamics. First, the organization of a logistics system integral to the global deployed capability of the USMC is crucial for operational commanders to have confidence in the logistics system. Building an effective distribution system rather than a supply chain focus is crucial to the future of USMC distributed operations. Second, such an approach requires technology and process that are operating within the USMC decision-making system and not the other way around. “There has been a continuing perception by those not close to our efforts that LogMod is about moving the USMC from the ‘iron mountain’ (which is basically heavy stockpiling) We never embraced the “just in time logistics” approach as the goal. LogMod is about finding the middle ground between the two extremes.”

From Desert Storm to OIF: The Drive for Reform

The concept of modernizing logistics systems has been on the books for decades, for the simple reason that most equipment and information technology (IT) solutions were put in place to the early 1970’s and required new organizational processes to get full effect from their implementation. According to Colonel Turlip, even though some of these systems could still – technically – fulfill perfectly well the function they were assigned for, their use could never be maximized, because of the lack of an efficient overarching architecture and appropriate organizational structure. Indeed, many of the issues addressed today first became crystal-clear during Desert Storm:

- lack of communication and interfaces between multiple systems (more than 200);

- absence of trust in the supply system and resulting tendency to over-request supplies and to create a giant recycling challenge;

- Numerous choke points and pipelines.

As a result of this state of affairs and frustrations on the ground, the Marine Corps undertook in 1998 a new initiative called “Integrated Logistics Capability Effort” (ILC), which was initially designed as principally an IT modernization reform and was struggling to be designed, executed and implemented prior to Operation Iraqi Freedom (OIF).

According to a 2004 USMC information paper,

“The initial attempts to gain position in the POM [Program Objective Memorandum] failed in both FY00 and FY02. At this time, the initiative was named the Integrated Logistics Capability (ILC) and had no clear support within the logistics domain or the operational community. However, in POM 04, GCSS-MC [Global Combat Support System – Marine Corps] succeeded as an “above-the-line requirement” and provided program of record status for the high visibility modernization effort.”[1]

OIF – which turned out to be a true “logistics war” – and what was perceived as a low-level priority became an essential objective to win the GWOT. Even though OIF I was a major success during which the First Marine Expeditionary Force (I MEF) covered the longest ground distance in USMC military history thanks in large part to an efficient and fast-adaptable logistical support, the military leadership brought back from this experience a list of flaws in the system, which had not been solved since Desert Storm and needed to be corrected as fast as possible:

“Our greatest shortfall during OIF was the lack of in-transit visibility information to incorporate into our command and control effort. (…) The lack of asset visibility on unit stocks and in-transit visibility on ordered items made it difficult to identify actual shortages, to locate needed items within stocks for reallocation, and to direct and track the movement of ordered items to requesting units. This lack of visibility resulted in delays, shortages, and at times an inability to expedite critical parts.

Another challenge was the difficulty in passing requisitions to the supporting Theater Support Command for common item support due to the non-compatible supply and warehousing information systems.

The material distribution process was cumbersome at best. Containers and pallets that were multi-packed for various units across the services had to be broken down and manually sorted then rebuilt before delivery to the tactical end user and added significantly to the distribution timeline.“[2]

Indeed, Colonel Turlip and his staff emphasized the “visibility challenge” as the major issue they addressed immediately in the aftermath of OIF I: what was considered a necessary incremental process of change rapidly became a front-burner preoccupation. In 2003 ILC became what is now known as LOGMOD for Logistics Modernization, which scope goes well beyond the initial IT reform to encompass the whole end-to-end logistics process across the USMC.

The Seven Initiatives of LOGMOD

As far as the United States Marine Corps is concerned, LOGMOD is, in Lieutenant General Richard Kramlich’s words, “a Corps-wide, multi-year, people-focused program to improve processes and technology supporting MAGTF (Marine Air Ground Task Force) operations” and aims at enhancing “MAGTF effectiveness by providing increased accuracy, reliability, and responsiveness of logistics information to Marines deployed on the battlefield.“[3]

It includes seven major initiatives evolving along the ongoing transformational operational concepts for 2015 and beyond – namely Marine Corps Strategy 21, Joint Vision 2020, Expeditionary Maneuver Warfare, and Sea Basing – These initiatives are the following[4]:

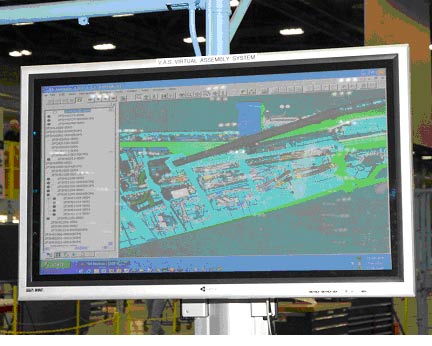

- GCSS-MC – GLOBAL COMBAT SUPPORT SYSTEM – MARINE CORPS – is the technological backbone and the information technology (IT) architecture of LOGMOD. It is a “portfolio of systems that support logistics elements of command and control, joint logistics interoperability, and secure access to and visibility of logistics data“[5]. It encompasses two systems: GCSS-MC/LCM – Logistics Chain Management – is a program designed to retire outdated systems and replace them with “integrated, distributed, web-based, off-the-shelf solutions“. The first phase of this program – GCSS-MC LCM Block 1 – is on track to be tested in July 2007, operational in FY08 and fully deployed in FY09[6]. The recommended location for the initial deployment is Okinawa. The second system – GCSS-MC – will provide an automated command and control support.

- Log OA – LOGISTICS OPERATIONAL ARCHITECTURE -, as defined by the Marine Corps, is their “blueprint for how logistics support will be managed, integrated and provided to meet strategic objectives and future operating concepts” It is in fact the overarching support structure designed to ease the transition towards “Logistics Chain Management (LCM) practices”.

- Log C2 – LOGISTICS COMMAND AND CONTROL – provides information and communication tools to allow the Commander to match logistics needs with ongoing operations: “synchronizing MAGTF C2 and Logistics Chain Management (LCM), C2 supports Marine Corps Operations in a network-centric (net-centric) environment through shared understanding of logistics capabilities, constraints and opportunities.“

- MAGTF DISTRO – MARINE AIR-GROUND TASK FORCE DISTRIBUTION – is a response to the shift of the threat towards asymmetrical warfare and the need to supply smaller dispersed units for longer periods of time and from further. Centralization (a “single integrated process”) and full visibility (a “transparent distribution chain”) are the main objectives of this initiative.

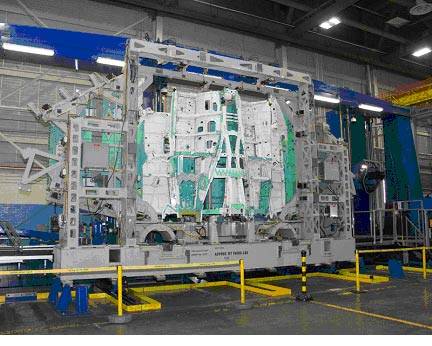

- MLG ReOrg – MARINE LOGISTICS GROUP REORGANIZATION – has been created to restructure the Force Service Support Group (FSSG) from a deployed perspective before taking into consideration the garrison perspective. Improving the effectiveness and adaptability of the supporting units to current and future demands on the battlefield has been the objective of this initiative and has driven mission changes.

- RoM – REALIGNMENT OF MAINTENANCE – basically consists in the streamlining of the maintenance process, eliminating redundancies and realigning itself to the ongoing redesign of the logistics chain/network. The official definition of RoM calls for “a ground maintenance system/capability that operates in three levels of maintenance (Operator/Crew, Field, and Sustainment) and improves ground maintenance effectiveness and equipment operational capability.“

- RoS – REALIGNMENT OF SUPPLY – aims at revamping the entire inventory process and warehouse management and bring it up to date to the new operational requirements and the XXIth century’s technologies. This means not only restructuring the organizations in charge of the inventories, but also the process of request itself: indeed one of the goal is to “centralize the responsibilities for order fulfillment, and the capacity management of both inventory and procurement in one supporting unit for each MAGTF“. Another requirement is to work jointly with other agencies and programs, such as for instance the Naval Logistics Integration.[7]

The approach used by the Marine Corps seeking to be in a position to restructure their IT system from beginning to end has been first to do a basic assessment of what they had, could keep and should replace (this IT system approach is discussed elsewhere on the website). The result of this assessment is reflected in the Systems Realignment and Categorization (SRAC) Project final report issued in September 2003.

The recommendations were to eliminate 36 no/low value legacy AISs or Automated Information Systems and 91 high value AISs. This meant that the Marine Corps should retire 66% of its high value AISs[8]. A migration strategy has since then been adopted and implemented to put in place a common database (SDE or Shared Data Environment) and a “portfolio of systems” allowing for better access and more flexibility.

Source: Randy Delarm, Global Combat Support System – Marine Corps/Logistics Chain Management Block 1, ACAT IAM OIPT MS A Decision Brief, 12 May 2004.

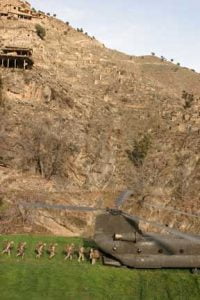

The Crucible of War

Colonel Turlip stressed that the press of military operations in Afghanistan and Iraq have acted as a major catalyst to go beyond a conceptual approach and to start implementing the needed changes right on the battlefield. That is how the “first major reorganization in close to forty years“[9] is now underway. They hence went from an “Iron Mountain” prospective to a “just in time” approach and are moving to a “just enough” one. Indeed, from OIF I in 2004 to OIF III in 2005, the complaint of the warfighter apparently went from “Where’s my stuff? ” to “When am I going to get my stuff?“[10].

According to Colonel Turlip, they soon discovered that to improve the identified ITV (In-Transit Visibility) and C2 (Command and Control) issues required a complete reappraisal of the processes and structural organization underlying the logistics approach. Indeed a true cultural change in the logistic world has been taking place.

As a result, three key aspects of the modernization could be labeled as de facto mini-revolutions on their own:

- The first aspect is the willingness fully to “shift the responsibility of logistics from the supported unit to the supporting unit”: logisticians in the Marine Corps are and should be warfighters (“Every Marine a rifleman”, as the USMC tenet goes), but the warfighters should not have to worry about where and how to get re-supply. The idea of a single point of contact and a simplified chain is now close to implementation on the ground.

- The second is the imperative to have the exact same organization “whether at home or deployed”, so that there is no time lag when a crisis does occur;

- The third aspect is the concept of near real-time information available almost end-to-end of the chain: from this point of view, in Colonel Turlip’s words, “OIF II and III took RFIDs to the next level.” With USMC operating forces tagging pallet-level sustainment with RFID, supported units are now able to view and track their sustainment requisitions from the moment they enter the distribution pipeline. The warfighters now have visibility of their supply and are demanding better distribution support. Other technologies and systems are crucial to achieve the desired “factory-to-foxhole Last Tactical Mile (LTM) visibility.” This has pushed the effort from visibility to distribution of key required capabilities.

FROM “NON-INTEGRATED STOVE-PIPED, INDEPENDENT PROCESSES”

Source: The LOGMOD Story: How we got here, where we are going! Official Marine Corps website for LOGMOD as off June 2007

TO A SINGLE “INTEGRATED CROSS-FUNCTIONAL END-TO-END PROCESS”

Reorganizing the garrison and collapsing echelons from five to three in the chain of command have been the direct results of the re-thinking, which allowed enhanced efficiency on the battlefield and also freed resources to invest in better IT systems. “Organizational change started with activating the Material Distribution Company within the 2d Supply Battalion, 2d FSSG. This reorganization created a single process owner for distribution process control and visibility. It combines under one commander the Marines, capabilities, and functions that formerly resided in several different FSSG [Force service Support Group] battalions and base organizations, allowing the logistician responsible for MEF requisitioning , be it the supply battalion commander in a garrison environment or the general support combat logistics regiment (CLR) commander when deployed , to exercise C2 of the entire requisition-to-receipt process across the MAGTF [Marine Air-Ground Task Force].“[11]

It is in this context that the MAGTF Distribution Center (MDC) has been created within the operational forces and has since been playing a crucial role, whereas in OIF I the distribution aspect of logistics was still largely ignored.

The Role of Oracle

The USMC has pursued an industrial partnership to shape their new logistics approach. Oracle was selected by the USMC to provide enterprise wide solution approaches via modern IT in 2004. According to their press release at the time, they were to deliver:

- “Industry standards-based functionality that complies with the U.S. Marine Corps Logistics Enterprise Architecture;

- Interoperability with other Department of Defense organizations and commercial partners;

- Provide a needed replacement for the 1970s-vintage, batch-processing supply and maintenance legacy systems; and

- Reduced training time, allowing Marines to serve more time in operational forces.”[5]

The selection was done after a several year effort of the USMC working through the processes which they felt they needed to craft an appropriate logistics system. The technology part was selected to serve the process re-engineering effort and not the other way around. Then the USMC selected Oracle Consulting as the systems integrator to work through the design effort to stand up the GCSS-MC program.

The selection in November 2006 of Oracle Consulting was seen by the USMC as a logical extension of the selection of the Oracle IT approach. According to a December 2006 LogMod SITREP, “GCSS-MC previously selected Oracle e-business software for its program. Consequently, a good team relationship has already emerged between GCSS-MC and Oracle Consulting. This synergy has carried over to the systems integration pieces as Oracle is already familiar with the Marine Corp’s objectives for GCSS-MC.”[6]

The Oracle-GCSS-MC teams stood up the initial Block 1 of GCSS in 2007. The GCSS-MC program office conducted Operational Tests and Evaluations starting in 2007 which ran through 2008. GCSS Block One began fielding to selected units in 4th Quarter of FY08

Block one is largely focused on logistics chain management with an eye to crafting a more effective distribution system for deployed troops. At the heart of the reform is the effort to have no gap between peacetime and wartime approaches to logistics management. Because if there are significant gaps, deployed commanders do not have confidence in the logistics systems and the lack of confidence creates the tendency to stockpile and to subvert the efforts to build a robust and effective system.

The Challenge of Metrics

Lessons learned from Iraq and Afghanistan are carefully analyzed and exploited through various mechanisms and centers (such as the Logistics Readiness Combat Center – LRCC -) and the feedback comes from the Marine Corps Center for Lessons Learned in Quantico[12], once the data is analyzed. In the past years the LRCC has for instance developed several “key information products” such as:

- “Force closure and major unit movement summaries complete with flight information, departure, and arrival times.

- Events chronology.

- Location of forces/logistics resupply points.

- Maritime prepositioning force (MPF) dispositions for all three MPF squadrons.

- Status of all MSC [Military Sealift Command] shipping supporting worldwide operations.”[13]

According to Colonel Turlip, the metrics being used – whether “order shipping time, repair time, node-to-node transportation time, etc.” – are still imperfect, but they help build a “performance measurement plan”: it is indeed better to rely on “just a few metrics which actually mean something” rather than on a large potentially confusing number of data. In 2005, the following improvements were already noticed using a few metrics, allowing rapid and drastic changes in the way to operate.

The immediate result, as stressed by Colonel Turlip, was an increase of the level of trust in the system and a major decrease in the number of re-orders multiple request submissions (which were pretty typical of past operations).

A Pragmatic Approach

The USMC is taking a measured and pragmatic approach to logistics reform. They are seeking to solve the distribution problem as the key “choke point” in logistics reform in order to enhance the capability of the MAGTAF. After all, the goal is to increase the lethality of the MAGTF by extending its operational reach through improved training, processes and technologies. And according to Major General Robert Dickerson, Commanding General, Marine Corps Installations East, “foremost consideration should be given to enhancing the capabilities of the MAGTF on the move. Since maneuver warfare is the essence of expeditionary operations, any system we field must fully support that doctrinal pillar.”[14]

A key element of working a pragmatic approach is the use of LogMod Wargames to shape the new acquisition approach. The first Wargame was held at Quantico from October 30-November 3, 2006. We have assessed the games in 2007 and 2008 in articles elsewhere on the website. The goal of the wargame approach is simple: “We have validated as much as we can theoretically and now must be able to translate roles and responsibilities to the Marines who must perform the actions, according to Lt. Col. Manning, Deputy Director, LogMod Transition Task Force.[15]

Col. Turlip emphasized throughout the interview the impulse of war to craft more effective logistics. Logistics is about distribution to deployed forces who trust a system that delivers “just enough” logistics. The roll out of the new system is to be in block increments but is being used by forces operating in real military operations today. It is an experiment that must become effective reality for the MAGTF. And through block roll-outs, simulations and wargaming, pragmatic reshaping of the roll out can be effective as the USMC faces its future. But today effective logistics is not about sustaining the iron mountain; it is about an effective global deployed force.

This article first appeared in Military Logistics International in June/July 2007 and was written by Murielle Delaporte and Robbin Laird

[1] USMC Information Paper,

Program Objective Memorandum (POM) Planning and Execution for Logistics Modernization, 7 April 2004.

[2] Testimony of Brigadier General Edward G. Usher III, Director Logistics Plans, Policies and Strategic Mobility, United States Marine Corps, before the House Armed Services Committee, Subcommittee on Readiness, U.S. House of Representatives, Regarding Logistics, March 30, 2004.

[3] Lt Gen Richard SW. Kramlich, Deputy Commandant, Installations and Logistics, in welcoming page of the official Marine Corps site for LOGMOD, as off June 2007 (https://logmod.hqmc.usmc.mil/).

[4] See: Patrick Anthes, Global Combat support System-Marine Corps (GCSS-MC): Presentation to the Advanced Logistics Officers Course, 5 March 2007.

[5] Patrick Anthes, GCSS-MC Presentation to the 2-07 Tactical Logistics Officers Course, 29 January 2007.

[6] For a detail of GCSS-MC Block 1 mission tasks, see: https://logmod.hqmc.usmc.mil/gcssmc/block1.html

[7] Official website of LOGMOD, ibid, see “initiatives” folder.

[8] Marine Corps Systems Command, Systems Realignment…, ibid, p.48 in particular.

[9] Colonel Turlip, quoted in: Marine Corps Presents at DoD Architectures Summit, https://logmod.hqmc.usmc.mil/.

[10] See: BGen John E. Wissler and Col. Peter F. Talleri, Meeting the Mandate for Change in Marine Corps Logistics: Logistics modernization efforts in OIF III, Marine Corps Gazette, August 2005, p.25 (www.mca-marines.org/gazette).

[11] BGen. John E. Wissler…, ibid, p.25.

[12] Oracle Press Release, U.S. Marine Corps Selects Oracle ® to Enable a More Effective Force: Oracle Applications to Support Global Logistics Chain Management, 25 October 2004.

[13] “Marine Corps Partners with Oracle Consulting for Global Combat Support System Marine Corps Systems Integration,” LogMod SITREP (December 2006).

[14] For more information, see: http://www.usmc.mil/ and www.mccll.usmc.mil/.

[15] LtCol Hank Malanowski, “The Role of the LRCC in the Global War on Terrorism”, Marine Corps Gazette, August 2005, p.37.

[16] “GCSS Roll-out Plan Being Crafted,” LOGMOD Leger (Volume II, Issue II), p. 4.

[17] “First LogMod Wargame conducted at Quantico,” LogMod Ledger (Volume 1, Issue 1, November 2006, p.1.

———-

***Posted August 13th, 2009