2017-11-10 By Robbin Laird

The F-35 undergoes final assembly and checkout at three plants around the world – in Italy, in Japan and in Fort Worth, Texas.

The Italian and Japanese lines are low rate production lines whereas the Fort Worth line is the high rate production facility.

The Fort Worth line is truly a unique manufacturing facility, which highlights why the aircraft can be built in high volume and why innovation can continue in the future as the line evolves.

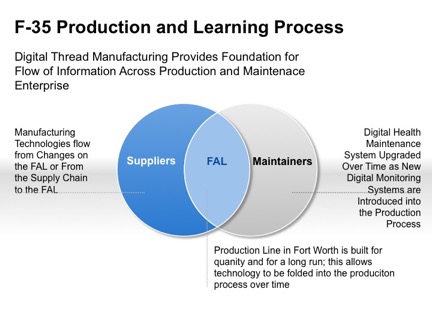

The line is based on a digital thread manufacturing model and as such can embrace evolving capabilities in the domains of automation as well as the various dynamics of change within the broader digital domain, whether commercial or military.

The current plan is to fill out the current manufacturing facility in Fort Worth by 2021 when full rate production is achieved at about 150 aircraft for the year.

I last visited the FAL in 2015 and a lot has changed with the ramp up in the past two years.

During my visit on September 25, 2017, I had a chance to tour the factory with Don Kinard, an F-35 manufacturing expert.

During my visit on September 25, 2017, I had a chance to tour the factory with Don Kinard, an F-35 manufacturing expert.

He has been my guide on previous factory visits.

I had a chance to interview Kinard after the visit.

And in that interview, he highlighted the ramp up process.

Question: What is the production rate this year?

Don Kinard: “There are more than 250 production aircraft in the field currently; there are 160 in assembly production across the globe, and the production rate at the Fort Worth facility this year is roughly five a month.

“The plan is 66 aircraft this year; more than 90 aircraft next year; and over 130 in 2019.

“And over the next 10 years about 50% of those planes are being produced for the partners.

Question: During the ramp up you are adding new staff.

What is planned during that period?

Don Kinard: “We have about 1,500 mechanics right now.

“We will roughly double that over the next three years.

“The mechanics are the touch labor personnel and we will increase the support labor by a few hundred people as well.

“During your tour of the training facility, you saw how we are augmenting training.

“The key in adding workers is to bring them up to speed prior to entering the assembly line to reduce downtime impact of integrating new workers onto the line.

“The mechanics are the main hire, and they’ll be going through three to six weeks’ worth of training on realistic components prior to going to the floor to do the jobs for which they are being trained for.

“Finding those mechanics has been something we’ve been working on now for years.

“We’ve had several hiring events all over the country.

“And we’re even starting to get people who have worked F-35 in the field.

“They’re now becoming available.

“They’re retiring from the military or leaving the service, and we’re now able to get people who actually worked F-35’s out in the bases as well as mechanics new to the program”.

Question: During the training facility tour, you highlighted ways the mechanics are being trained realistically prior to going to the final assembly line. How would you describe that process?

Don Kinard: “We are using a number of assembly simulators to provide hands on training necessary to ensure that the mechanics are receiving realistic experience prior to joining the assembly line team.

“We are working to make the transition from training to the real plane as seamless as possible.

“First of all, we hire trained aerospace mechanics.

“Secondly, we train them to be F-35 mechanics on realistic components, and then they go to the floor and get teamed up with people that have been on the floor a while, and that is the on-the-job, or OJT, phase of the hiring and training process.

“What we’ve seen so far with some of the classes that are complete is a tremendous improvement in quality on the mechanics first forays onto the floor.”

Question: In addition to adding mechanics and support labor, you are ramping up automation throughout the assembly line as well. What has been that impact?

Don Kinard: “We have had a touch labor reduction of 75% over the last five years on the airplane.

“There are a couple of advantages we have with regard to modernization of the final assembly line.

“First, we are building a significant number of F-35s looking out into the future, so we’ve been able to invest, as a company, in technology to do more automation, something we didn’t have the opportunity to do in past programs.

“Second, the technology behind the digital thread has exploded in the past five years, meaning that, we started out with 3D solid models years and years ago and we planned for a certain amount of automation. Since program inception automation has gotten a lot better and less expensive.

“The ability to put the digital thread in the hands of the mechanics is something that’s evolved over the last five or six years, and now we are able to actually take 3D scans to compare the as-built aircraft directly to the as-designed aircraft.

“This capability has only been around for three or four years.

“There has been an explosion of digital thread technologies– augmented reality, laser projection, optical projection, the scanning white lights, scanning lasers–that we can leverage and work into the assembly line.

“We’re able to do that because we have 2,500+ more aircraft to go.

“So there’s a big economic incentive for us and our customers to make those investments through capital investments and the Blueprint for Affordability Program.

“And, by the way, digital technologies continue to evolve rapidly, and because we have a digital thread line and a Manufacturing Technology organization we can incorporate those technologies as appropriate.

“We’ve only started with augmented reality, but I almost guarantee you that in the next five years that’ll change everything. All of the Internet of Things, IToT, Industry 4.0, will be incorporated as appropriate. We will have the ability to automate a lot of reporting, automate a lot of data gathering, automate a lot of things today we do manually.

“Because of our digital thread approach we can incorporate innovations from the commercial space, which creates opportunities to improve quality and reduce costs.

“Our digital thread manufacturing process provides us with the opportunity to do so on an open-ended basis.

“This aspect of innovation built into the F-35 program is not widely appreciated.

“We’re able to harness the power of the major digital companies out there developing technologies in the commercial space, and spending enormous amounts of money, and all of a sudden those innovations are flowing our way.

“Having the three variants on the same assembly line has allowed the F-35Cs and Bs to benefit enormously from the evolutions of the largest production run of the three, the F-35A.

“The avionics and the software are the same across all three aircraft, which is a huge learning, and maintenance advantage.”

Question: Because of the digital thread approach, the changes on the manufacturing line are informed by and can inform the stand up of the global sustainment effort as well.

How would you describe this process?

Don Kinard: “One needs to look at sustainment much like you look at manufacturing learning.

“We’ve done a lot of learning over the past five years.

“We know how to build the aircraft now.

“That mystery is gone.

“Now, we’re learning how to sustain that aircraft, and that data will be captured by systems like ALIS (advanced logistics information system).

“We can then shape a global database as flight data accumulated so that everybody gets better.

“Everybody who has an F-35 gets better.

“With more than 250 planes out in the field, we are getting data from these aircraft and incorporating lessons learned into changes on the FAL itself.

“This is the advantage of having a digital data stream to work with from design to manufacturing to sustainment and back again.

“This allows for a digital learning curve, which enables both quality and performance to be enhanced.

“If customers take full advantage of the process, sustainment will be enhanced and sortie generation rates ramped up for the global F-35 fleet.

“In addition, many of the manufacturing technologies developed for Production have applications with our Sustainment business, additive manufacturing of tools and augmented reality delivery of maintenance instructions being a couple of good examples.”

During the factory tour, it was clear that ramp up was ongoing and that a number of changes and upgrades had occurred since my last visit in 2015.

First, throughout the factory there are a large number of overhead RFID panels which monitor the parts and tools throughout the factory so we can track by the use of digital devices where parts are and how they are being consumed, and also using our integrated business systems what the current manufacturing state status of each aircraft is at every production station.

According to Kinard: “The focus is upon providing data to those who use it on the floor, as well as to provide a data dashboard overview for management on aircraft status and performance.

“Much of this capability is currently available on our phones by use of an app called Plane-Site developed by our Production Control an IT departments and more capability is being added every year.”

Kinard emphasized during the tour that the 4th industrial revolution which revolves around leveraging data to get enhanced understanding of production processes to improve continuously the production process was a core focus of the overall data management effort.

During the tour we saw a new automated wing-drilling machine, which provides a significant improvement in how it operates, including waste material reduction, automated hole measurement, enhanced accuracy and improved speed.

According to Kinard: “Lockheed Martin is developing with the US Government a number of technologies to enhance performance and lower cost for the supply chain as well. One example in the factory was a new titanium cryogenic machining system.

“This cryogenic system was being tested to determine its effectiveness in cutting titanium and faster while increasing tool life. The Cryogenic machine tool uses a liquid nitrogen tank, which feeds liquid nitrogen to the cutter tip

“Given that 25-30% of the plane uses titanium, any reductions in tooling costs are significant for suppliers who are the targets of this machining technology.

“More generally, given the significant investments in machine tools to build a modern fighter aircraft, improvement in efficiency is a major plus.

“Enhanced use of robots could be seen throughout the factory.

“One example was Thor, a robot used in the finishing shop to inject coatings onto the airplane in the finishes area.

“The robot along with automated 3D scanning technologies is designed to manage the thickness of the coatings, which is part of building a low observable aircraft.

“This development leads to reduction of time and improvement in accuracy as well.

“One result of the use of automation and associated accuracy improvements can be seen in the significantly low defect rate. 80+% of F-35s from the FAL go to the Radar Cross Section (RCS) facilities with zero defects.

“Scanning technologies are clearly going to be leveraged for improvements in accuracy and speed as well.

“The basic approach is to use scanning technologies, which scan the plane as-built and then directly to the plane compare it to as-designed in the CATIA models. This process can identify any final adjustments needed. The goal is to use this more broadly to reduce the need for manual labor to perform these tasks.

“One example in testing is using scanning technology to 3D scan the bomb weapons bay as opposed to a manual fit check of simulated weapons.

“This is a work in progress but clearly one which can provide for further manufacturing improvements.”

“The broader point is simply because the FAL is built on a digital thread line it is possible to have open ended innovations and production learning, which can also be applied to the Sustainment process going forward, as well as learning from the performance of operational aircraft integrated with production process itself.”

For an overview on digital thread manufacturing, see the following:

https://www.dodmantech.com/ManTechPrograms/Files/AirForce/Cleared_DT_for_Website.pdf

Editor’s Note: The past discussions with Don Kinard can be found here:

https://www.sldinfo.com/shaping-f-35-production-maturity-a-dialogue-with-dr-don-kinard/

https://www.sldinfo.com/visiting-the-f-35-final-assembly-line-fort-worth/

https://www.sldinfo.com/an-update-on-f-35-manufacturing-the-case-of-wing-assembly/

The photo above can be found here: