2015-03-22 By Robbin Laird

UID and RFID technologies have been important enablers of change in the world of logistics.

But one can be forgiven for confusing the technology with the outcome.

The new technologies can provide sensor data on things in motion; the challenge is to turn that data into information, which can govern events to be managed by clear business rules in order to shape a more effective logistics management effort.

But it is also important to realize that wireless sensors are really just at the beginning of their impact on transforming operations, including those which are associated with logistics.

In an important book looking at the potential impact of wireless sensor networks on a variety of activities, the authors Feng Zhao and Leonidas Guibas underscored how they saw the transformational impact of wireless sensing:

Advances in wireless networking, micro-fabrication and integration (for example, sensors and actuators manufactured using micro-electromechanical system technology, or MEMS), and embedded microprocessors have enabled a new generation of massive-scale sensor networks suitable for a range of commercial and military applications. The technology promises to revolutionize the way we live, work, and interact with the physical environment.

In the not-too-distant future, tiny, dirt-cheap sensors may be literally sprayed onto roads, walls, or machines, creating a digital skin that senses a variety of physical phenomena of interest : monitor pedestrian or vehicular traffic in human- aware environments and intelligent transportation grids, report wildlife habitat conditions for environmental conservation , detect forest fires to aid rapid emergency response, and track job flows and supply chains in smart factories.

Unlike current information services such as those on the Internet where information can easily get stale or be useless because it is too generic, sensor networks promise to couple end users directly to sensor measurements and provide information that is precisely localized in time and/ or space, according to the user’s needs or demands.[ref] Zhao, Feng; Guibas, Leonidas (2004-07-21). Wireless Sensor Networks: An Information Processing Approach (The Morgan Kaufmann Series in Networking) (Kindle Locations 281-290). Elsevier Science. Kindle Edition.[/ref]

And in a recent article published March 20, 2015 on how wireless sensors can be used in the health care industry, the ability to harvest information from such sensors in tracking the movement of health care professionals has been highlighted:

Wouldn’t it be cool track in detail how staph moves from person to person in the real world?

Some French researchers tested a way to do it. They outfitted 261 health care workers and all 329 patients in a long-term care hospital with wireless sensors that recorded their interactions with one another every 30 seconds.

The researchers also took weekly bacterial samples from the people’s noses and used genetic tests to fingerprint the staph. That way the scientists could trace the movement of bacteria from person to person.

The scheme worked.

Over four months of tracking and testing, the researchers mapped the hops that bacteria made from one person to another to another. They documented 173 transmissions of staph between people in the study. About a third of patients who had been free of staph when admitted were colonized within a month.

The findings were published Thursday by PLOS Computational Biology.

“Bottom line is, monitoring contact networks is easy,” Thomas Obadia, lead author of the research paper, tells Shots in an email. “Recorded signals are indeed correlated with transmission, so such data should be used to design targeted control measures, in hospital or [a long-term care facility]. While this is more of a methodological paper, we’re now trying to use the same data in a more applied way, but again this part is still a work in progress.”

The ability to leverage information generated by wireless networks is a key element of shaping the factory of the future, and managing supply chains much more effectively.

But to do so is not just about leveraging RFID systems; it is a broader effort which requires new approaches and systems.

At the time of GlobeRanger’s purchase by Fujitsu, one Dallas Business Journal writer described the acquisition this way:

GlobeRanger has been operating since 1999 and has grown to employ about 20 people who have helped contribute to the development and promotion of its iMotion Edgeware platform, which works to simplify the development, deployment and management of RFID, mobile and sensor-based solutions.

The focus of this writer was upon GlobeRanger’s proprietary “secret sauce,” namely the iMotion Edgeware platform and correlated solution sets.

The company has created a proprietary software engine –iMotion – which has underpinned a family of enabling solution sets which the company has grown from one to several enabling solution sets.

Those enabling solution sets have then been applied to different product areas and a diversity of industry experience has been generated which then in turn allows a cross fertilization to other industrial experiences.

For example, this means that the defense solution sets have benefited from the commercial experience of GlobeRanger and vice versa.

What can be missed is that the shift in logistics management enabled by the new technologies is really a cultural shift.

Rather than having supply chain of segments dependent on local reporting sent back to the core, what can evolve is domain knowledge of the supply chain itself with appropriate levels of decision making to the relevant domain knowledge base.

It is also about enhanced safety and security in terms of creating more capable supply chain custody control, which with regard to defense and security items is not just nice to have but indispensable to the performance of the entire enterprise.

The chart below provides a snapshot explaining this process of development and interaction involved with the GlobeRanger approach.

According to GlobeRanger, the key foundational element by which they have generated innovative logistical solutions is built around iMotion inside various solution sets.

GlobeRanger Corporation pioneered the creation of an information processing software infrastructure at the edge of the enterprise.

This enables companies to harness data generated outside traditional IT environments to improve their business processes and move closer to being real-time organizations.

The advent of low-cost RFID tags and reader technology is creating a tidal wave of real-time, item level and sensor information.

In order to harness the value of this exponentially growing edge data, companies must have the ability to collect information from a variety of devices, apply business context to generate meaningful information and integrate with existing systems to determine appropriate action.

iMotion™ is built for production scale implementations of RFID/mobile/sensor technologies and provides the comprehensive infrastructure to control devices, manage networks and transform data to optimize business processes.

https://sldinfo.com/whitepapers/the-imotion-edgeware-platformreshaping-the-logistics-enterprise/

One of the core engines for logistical management underpinned by iMotion software has been GR-AWARE which is an asset tracking and reporting engine.

This software platform and core engines then are applied to a variety of industries and situations to lead to change in ways to manage logistics and reshape work processes to more effectively master the logistical and supply chains.

It is about using the flow of data from sensors to provide for automated solutions, which help reshape logistical management, rather than simply collecting data and storing it in a static manner.

It is about mastering the management of things in motion with a management system, which is agile, flexible and capable of mastering the chaos of movement.

In a second interview with George Brody, we discussed the iMotion platform and its relationship with GR-AWARE and the solution sets generated by the product, the process and the approach.

Brody: “Out of the box the iMotion platform provides for device connectivity. When we went to clients, most of those clients were looking for a 90% completed solution, rather than just leveraging the iMotion platform themselves. They were then looking to configure for multiple applications.

For example, with regard to the development of GR-LIVE we created a solution layer on top of iMotion which provides for various solution accelerators which then allows for dynamic inventory control. Logistic processes have a number of repeatable functions like shipping and receiving and the solution accelerators built into GR-LIVE allows the process to become more transparent, localized and effective.

In other words, with a system like GR-AWARE we have leveraged a number of solution accelerators and built a 90% complete solution that a client can configure and apply to his work flow for efficiency and effectiveness. It gives the customer solutions, not simply collecting data for his supply chain management and chain of custody.”

A key outcome of the GR-AWARE system is enhanced visibility of the supply chain and authentication of processes and data flowing through the supply chain.

With regard to GR-AWARE based Theater Deployment and Planning, Brody discussed its application to disaster relief.

“When you deploy to a theater or go to aide in a crisis, you would like to know what supplies are available locally to support your operations, notably things like fuel and water.

If you had set up pre-existing working relationships with suppliers in the region, and had awareness of what they had and where they had it, then you could focus on what you needed to bring into the region, and what you could obtain locally if only you had the knowledge.

And it is not just about an abstract knowledge; it is knowing exactly where things are and how they can be moved to where they are needed. In effect, these are logistical tools which can have tactical and strategic impact for forces operating in a local region for humanitarian assistance and disaster relief.”

Question: So instead of carrying your Walmart to the crisis area, you can shape a strategy to be able to tap into the Walmarts with closest proximity to the region?

Brody: That is exactly right.

And that is what an approach based on GR-AWARE can achieve.

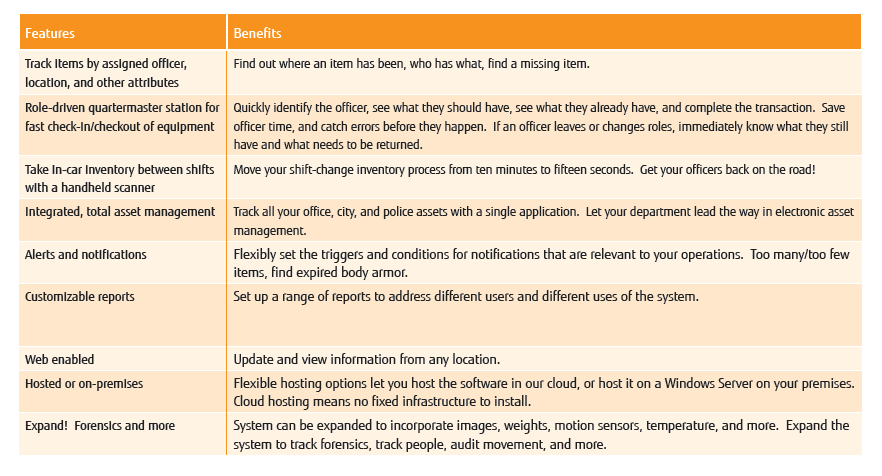

An example of how GR-AWARE works can be seen with regard to its application to the work of a police force. In a GlobeRanger piece on how GR-AWARE has been applied to asset management for police departments, the approach, which has been put in place for police departments, is described as follows:

It is more crucial than ever that police departments keep an eye on their inventory. Any item in the wrong hands can spell disaster, even an officer’s uniform.

Other items need inspection or maintenance, or simply have an expiration period, like personal protection vests.

Old methods of keeping track of these items are just not sufficient anymore. Whether it be a spreadsheet system or separate electronic systems, knowing who has which items and what the current status of those items are is vital to providing for public safety, thwarting police impersonation, and keeping the officers’ equipment in good condition.

GR-AWARE for Police Departments is the RFID and barcode-enabled asset management solution that provides a view of police department assets by assigned person, location and other attributes, but also the ability to tie into the HR system for an integrated system.

It also automates the processes of enforcing issued quantities, alerts for expired items, and more. It provides all-time visibility of not only who has what, but also what those people are supposed to have.

The system makes checking equipment in and out to police officers quick and easy, and reduces time for in-car inventory for shift changes, allowing the officers to spend their time protecting their citizens.

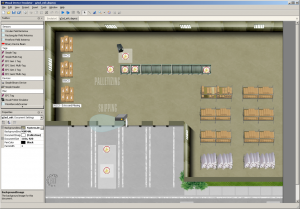

A key technology which has been developed by GlobeRanger allows the Department of Defense and companies to more effectively manage their work processes is an ability a to understand the impact of changes which can be introduced BEFORE they are actually introduced.

This capability is built around what GlobeRanger calls the Visual Device Emulator.

According to Brody, with the Visual Device Emulator, “I can have a global team of Fujitsu developers right now sitting around the world, or another partner with team around the world collaborating and working on the solution at their desktop without utilizing a single physical piece of hardware.

Then we can have the application running in a server somewhere on their shared network.

The team can then collaborate and test against it to determine the best configuration against the application set.

It’s also a really repeatable test environment. We can drive all these devices to produce thousands and thousands of transactions and you can test out the application for the testing quality of service.

For example, with the MRO application, using the emulator, you can drive a virtual plane into the hangar and determine the best hardware configuration in terms of sensors to deliver the data most effective to your work process.

And obviously, this helps shape effectively the requirements process as well for the emulator can allow the sales and product management teams to confirm the requirements with a customer in a visual emulated environment.

The application cannot distinguish the emulated devices from the real world deployment of sensors.

And the customer can see how the application’s going to work in real life, before they go out there and deploy it.”

In later interviews, I will deal with core case studies of most interest to the defense side of the equation remembering that the GlobeRanger solution set operates from a commercial base and is being applied to a number of commercial solutions as well.

https://sldinfo.com/whitepapers/the-visual-device-emulator-and-shaping-logistics-solutions/

For the first two articles in this series see the following:

https://sldinfo.com/managing-defense-supply-chains-shaping-a-21st-century-way-ahead/