By Robbin Laird

In the last article on the USS Gerald R. Ford (CVN 78), I looked at one key building block which enhances both the ops tempo of the strike package on the USS Gerald R. Ford as well the flexibility of the weapons packages which can be moved to the flight deck and loaded on the strike aircraft.

This is a key input into a significantly redesigned flight deck workflow which allows for a much more rapid turnaround of the launch and recovery of aircraft as well as more flexibility operating and arming the strike packages.

My flight deck visit was facilitated by Ford’s Top Catapult Officer (TOPCAT), Lt. Cmdr. Andy Kirchert and by Aviation Boatswain’s Mate (Fuels) 2nd Class Thomas Drew Watson (from Winona, MS).

Insights throughout with regard to the impacts of the workflow on operational tempo and combat impacts were provided by Lt. Christopher Warzinski, CSG-12’s Joint Interface Control Officer, Rear Adm, Craig Clapperton, Commander Carrier Strike Group 12, and by the USS Gerald R. Ford’s (CVN 78) Commanding Officer, Capt. J.J. Cummings.

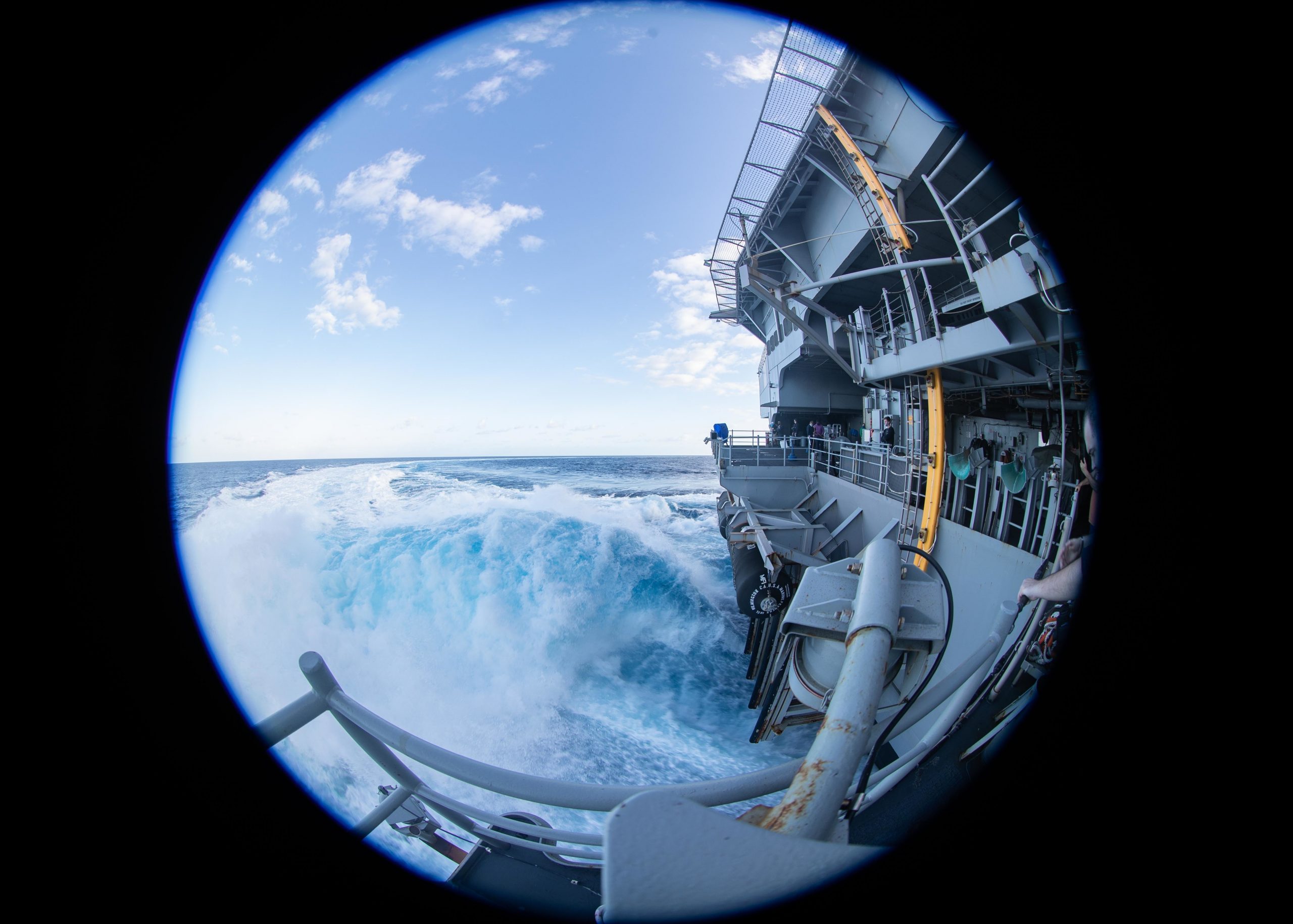

A major difference can be seen right away when one steps onto the flight deck. Next to the USS Gerald R. Ford (CVN 78) during my visit was the USS John C. Stennis whose flight island can be seen in the rear of this photo.

The island on the USS Gerald R. Ford has been moved 140 feet aft and is 30% smaller. What this allows is significant additional space for aircraft refueling and weapons loading operations, with the area forward of the island able to accommodate more combat aircraft.

During flight operations, Ford’s design increases the amount of usable space forward of the island and reduces the amount unusable space aft.

As the ship’s captain, Capt. J.J. Cummings, put it: “If you think of the ship as a gun, and the strike force as bullets, then we have increased the size of the clip because we can load it with more bullets because of the island being further aft on Ford versus Nimitz.”

The clam shell form factor for the weapons elevator flight deck hatches also open with minimal flight deck interference.

There is more operational space on the USS Gerald R. Ford’s flight deck and the new launch and landing systems as well as a significant redesign of how refueling is done on the flight deck provide key tools for a significant reshaping of the operational tempo for the large deck carrier.

The new launch system allows for a wider range of aircraft to operate from the carrier; the new arresting gear system can recover them. The ability to mix and match the current air fleet and the future one is significantly enhanced with EMALS. The launch system has a larger aircraft weight envelope that exceeds what is available with steam, so EMALS can launch very light aircraft or heavy aircraft which means this system can accommodate future manned or unmanned aircraft.

The same flexibility exists in the Advanced Arresting Gear with larger current operating wind and weight envelopes and the capability to recover future aircraft designs with minimal modifications required.

The refueling system is designed to keep a clear path to the catapult by reducing flight deck obstructions caused by refueling hoses, weapons skids and weapons elevator access points. This highly efficient flight deck flow allows for the FORD to sustain higher launch and recovery rates.

Let me turn to each of these capabilities which add up to a new workflow on the deck which provides for a more rapid pace of ops tempo and more flexibility to mix and match mission packages as well.

Much of the press about USS Gerald R. Ford has been about its launch system, the electromagnetic aircraft launch system or EMALS.

I discussed this system at some length with Lt. Cmdr. Andy Kirchert. There are several advantages of the system over the legacy steam catapult system which he highlighted.

First is the flexibility and adaptability of the system. The EMALS system has more room for growth for future aircraft systems. Steam will not be able to shoot super light aircraft and it can shoot heavy aircraft but that is serious wear and tear on the CAT when it shoots heavy shots. Heavy/light shots not an issue at all with EMALS.

Second, the new system has reduced manning requirements for the launch function. There is reduced manning by 50%.

Third, longer fly days are enabled due to reduction in the pre-flight and post flight procedures. For example, steam catapults require a heat up to be ready for launch

Fourth, the system is easier on aircraft which should led to reduction of stress on the aircraft due to launch. The system delivers very precise endspeeds for the launch process.

Fifth, the system delivers enhanced safety margins. The system will not allow launch of an aircraft if it sees something wrong in the process.

Obviously, there have been challenges with the system, but the Ford team is overcoming those challenges, but according Lt. Cmdr. Kirchert, “We are in the fine-tuning phase.”

One might note that both the French and Indian navies are lining up to procure EMALS which suggests confidence in the system.

The counterpart to the EMALS is the Advanced Arresting Gear system which provides capabilities to recover the current fleet of aircraft in environmental conditions that exceed what is possible with the Nimitz class system

And similar to EMALS, AAG is designed to have the ability to operate with aircraft of varying weights, including future aircraft systems. When one visits the Advanced Arresting Gear system below deck, it is amazing to see how automated it is and how little manpower is required to operate it as well.

The refueling system is a major aspect of the redesign of workflow on the flight deck. My guide to this aspect of the ship was provided by Aviation Boatswain’s Mate (Fuels) 2nd Class Thomas Drew Watson. Post flight, aircraft are parked along two isles for refueling – one on the deck edge and the other just outside of the landing area. This parking arrangement allows unobstructed access to the catapults.

The in deck refueling stations which are unique to the Ford keep refueling hoses out of the taxi paths to the catapult. (refueling stations which can refuel two aircraft at the at those stations.

This has a major impact because on the Nimitz the refueling crew has to carry several, lengthy connected fuel hoses which are heavy from the starboard side of the Nimitz class to do mid-deck refueling. On the Ford, the hoses are right there beside the in-deck refueling stations and rather than having to have a crew of 5 people to bring the hoses 150 feet to mid-deck and do refueling, you only need two crew to man the in-deck refueling stations.

Lt. Cmdr. Kirchert emphasized that the sensors that make up the system and the software which manages them have posed development challenges in the past, but that NAVAIR and General Atomics have worked effectively to provide for the software changes necessary to allow the system to function effectively. And many of the software changes are quickly phased into the system between underways.

Also in common with almost all new systems, parts failures have emerged which were not anticipated but those parts are being rebuilt to provide for better performance as well.

My topside visit ended with a discussion with by Rear Adm. Clapperton.

He underscored that the USS Gerald R. Ford was going to be a key enabler for the maritime distributed force which the Navy was envisaging as its way ahead for the fleet.

With an ability to provide flexible strike options to the fleet, and a capability to support new weapons, and new aircraft, the new generation carrier was a key infrastructure to support the way ahead facing the U.S. Navy, the joint and coalition force.

Featured Photo: A T-45C Goshawk, attached to Training Air Wing 2, prepares to launch from USS Gerald R. Ford’s (CVN 78) flight deck Sept. 11, 2020. Ford is seen underway in the Atlantic Ocean conducting carrier qualifications. (U.S. Navy photo by Mass Communication Specialist Seaman Apprentice Sarah Mead)