By Robbin Laird

As the fleet re-works blue water maneuver warfare and expeditionary operations from the sea, a key element of the effort is shaping an effective weaponization approach and strategy. Doing so is a work in progress and a major challenge for the United States and its allies.

During my discussions and visit to NAWDC, some elements which are crucial to shape an effective way ahead for the fleet, and the challenge as well of shaping the kind of training which will be needed to deliver the right combat effect at the right time were discussed.

The first point is pretty straightforward. The focus is upon how to shape fleet wide targeting.

This is part of the NAWDC-led effort to work TTPs for a force element, not just a single platform, or a platform operating off a single ship, such as Super Hornets working with an aircraft carrier.

The reason for this focus is rooted in a shift in how ISR is changing and how new options are becoming available for targeting, and as well how to do delivering targeting solutions.

This is what is implied in the shift from the kill chain to the kill web.

This was put particularly well by a senior RAAF commander in an interview I did with him in 2016. Because the Aussie Navy does not have an Air Force but relies on the RAAF to do the air part, they focus on integration at levels which in the United States requires two very large forces the US Navy and the USAF to work integrability.

“We need to be in the position where our maritime surface combatants are able to receive the information that we’ve got airborne in the RAAF assets. Once they’ve got that, they’re going to actually be trying to be able to do something with it. That is the second level, namely, where they can integrate with the C2 and ISR flowing from our air fleet. But we need to get to the third level, where they too can provide information and weapons for us in the air domain.

“That is how you will turn a kill chain into a kill web. That’s something that we want in our fifth-generation integrated force. And in a fifth-generation world, it’s less about who is the trigger shooter, but actually making sure that everybody’s contributing effectively to the right decisions made as soon as possible at the lowest possible level.”

A key element of the new approach is how platforms will interact with one another in distributed strike and defensive operations and enable cuing weapons across a task force.

The first point is rather significant—it is about how to leverage weapons capabilities across a task force and shaping an expanded capability and process for empowering third party targeting.

The second point is that there is a shift from a primary focus on deliberate targeting to dynamic targeting. As one analyst has put the issue of the shift affecting the maritime domain:

“Perhaps the most acute differences that the maritime theater will present are the target sets. Targets that can be categorized as deliberate will now be the exception to the rule. Relatively fixed land targets will yield to highly mobile maritime targets. Therefore, targets may be known but not fixed.”

This then highlights the importance of dynamic targeting for the fleet, a subject which I discussed last Spring with CDR Joseph Fraser, head of the Information Warfare Directorate, which has been designated the executive agent for targeting for the United States Navy.

In that interview our discussion focused on the evolving role of ISR enablement to a strike enterprise, and the challenges of working a kill web approach.

During the visit to NAWDC in July 2020, we continued that discussion. There is a clear need to expand targeting domain knowledge to include both non-lethal and lethal effects. Because the kinds of non-lethal effects as discussed with CDR Stephenson provide significant shaping functions in combat, non-lethal effects really need to factor into the entire sweep of how the strike function delivers combat effects.

CDR Fraser put it this way: “Nirvana for me is a fully integrated strike squadron capability that does both kinetic and non-kinetic missions to provide a range of options to the commander.”

Part of the challenge is putting in place a cadre of officers with the kind of strike domain knowledge covering both lethal and non-lethal who are not attached to a particular carrier wing. This would allow for the strengthening of the cadre and the ability to deploy to the operational need, rather than the operating cycle of a particular air wing.

The third point flows from the second. How to shape dynamic targeting knowledge and training, notably in terms of the dynamics of change both in terms of ISR availability and the evolution of the weapons enterprise?

How is one going to shape a training enterprise able to encompass fleet wide plus ISR (the MISR path) with knowledge of the various ways weapons which can be launched from air-sea-land locations to provide for the dynamic targeting required by the fleet?

The fourth point really would revolve around the weapons enterprise itself and how the fleet will be empowered by new ways to build out weapons arsenals and provide for adequate stockpiles for the force.

That was the subject of conversation with Captain Edward Hill, the oldest Captain in the U.S. Navy at sixty years of age. Because he goes back to the Cold War operating Navy, he can bring forward that experience to the return to the contested environment challenges facing the weapons enterprise.

Frankly, this was one of the most interesting interviews I have ever done with a Navy officer but will focus on only a couple of takeaways from that conversation. He is the head of the TLAM department and has been focused for some years on the challenges which TLAMS would face in a denied communications battlespace.

Although we discussed that issue, I am going to focus on three other issues which we discussed.

In addition to the readiness challenge which the U.S. Navy faced at the end of the last Admiration, the Navy has faced weapons shortages as well. Clearly, building adequate stockpiles of weapons is crucial.

But also important is working a new weapons mix to ensure that one is not forced by necessity to rely on the most expensive weapons, and the ones that will almost always have a stockpiling issue, but to have a much more cost effective weapons set of options.

As Captain Hill put it: “We need to get beyond golden bee- bee solution.

“We need to have a weapons barge come with the battle group that has an affordable weapons mix.

“We need $50,000 weapons; not just million-dollar weapons.

“We should have weapons to overwhelm an adversary with Joe’s garage weapons and not having to use the golden bee-bees as the only option.”

To get to this point raises a second aspect, namely, working out where one engages an adversary and what weapons mix one might need in that engagement area. With regard to the Pacific, in my view, as we address sea denial and sea control reaching out into the SLOCS, what weapons mix do we need in which particular engagement zone? It is not going to be all about hypersonic weapons.

The third point is about the C2 side of weapons engagement. As Captain Hill put it: “How do we train to be prepared for C2 disruptions and conflict in a high-end fight.”

For a strike force, this is the critical element of ensuring an ability to leverage a distributed weapons capability, but to do so with effective determined targeting solutions with the kind of tactical or strategic effect one is seeking. This means that C2 enabling an integrated distributed it force is not only a weapon but the foundational weapon enabling change in dynamic targeting for an innovative weapons enterprise.

One of the clearest expressions of the way ahead along these lines was an interview which I did in 2016 in Australia, with Rear Admiral Mayer, the commander of the Australian Fleet. This is how he characterized the C2 side of the weapons enterprise for an integrated but distributed force.

“The potential of each of the individual platforms in a network is such that we’ve actually got to preset the limits of the fight before we get to it. The decisions on what we’ll do, how much we’ll share, and what sovereign rights we will retain have to be preset into each one of the combat systems before you switch it on and join a network.

“There is no point designing a combat system capable of defeating supersonic threats and throttling it with a slow network or cumbersome C2 decision architecture. Achieving an effective network topology is so much more complex in a coalition context in which the potential for divergence is higher.

“The paradox is that a coalition network is much more likely a requirement than a national network, and yet what investment we do make is based on national systems first. If we don’t achieve the open architecture design that enables the synergy of a networked coalition force, then the effectiveness of the coalition itself will be put at risk. The moment we insert excess command and hierarchical decision authority into the loop, we will slow down the lethality of the platforms in the network.

“Before we even get in the battlespace, we have to agree the decision rights and preset these decisions into the combat system and network design; the fight for a lethal effect starts at the policy level before we even engage in combat operations.

“The network and C2 rather than the platforms can become the critical vulnerability. This is why the decision-making process needs to be designed as much as the network or the platforms. If the C2 matrix slows the network, it will dumb down the platform and the capability of the system to deliver a full effect.

“The nature of the force we are shaping is analogous to a biological system in which the elements flourish based on their natural relationship within the environment. We have an opportunity to shape both the platforms and the network, but we will only achieve the flourishing ecosystem we seek if each harmonize with the other, and the overall effectiveness is considered on the health of the ecosystem overall.

“For example, an ASW network will leverage the potential of the individual constituent platforms and that in turn will determine the lethality of the system. A discordant network connection will, at the least, limit the overall force level effect of the network and at worst break the network down to discordant elements.”

Clearly, a key part of the evolution is about shaping a weapons revolution whereby weapons can operate throughout the battlespace hosted by platforms that are empowered by networks tailored to the battlespace.

And that revolution will have its proper impact only if the network and C2 dynamics discussed by Rear Admiral Mayer unfold in the national and coalition forces.

“The limiting factor now is not our platforms; it’s the networks and C2 that hold the potential of those platforms down.

“When the individual platforms actually go into a fight, they’re part of an interdependent system[;] the thing that will dumb down the system will be a network that is not tailored to leverage the potential of the elements, or a network that holds decision authority at a level that is a constraint on timely decision[-]making. The network will determine the lethality of our combined system.”

The strategic shift from the land wars highlights the growing role of dynamic targeting in a contested environment.

And as new platforms and capabilities come into the force, they can be looked at in terms of how these new capabilities empower a kill web force, rather than simply fitting into the older kill chain appraoch.

For the U.S. Navy at NAWDC, the next generation carrier, the USS Ford can be viewed from this prism.

My visit last week to the USS Ford will highlight how indeed the next generation carrier is best understood from the standpoint of being able to deploy an integratabtle air wing and empowering interactive maritime kill webs in the extended battlespace.

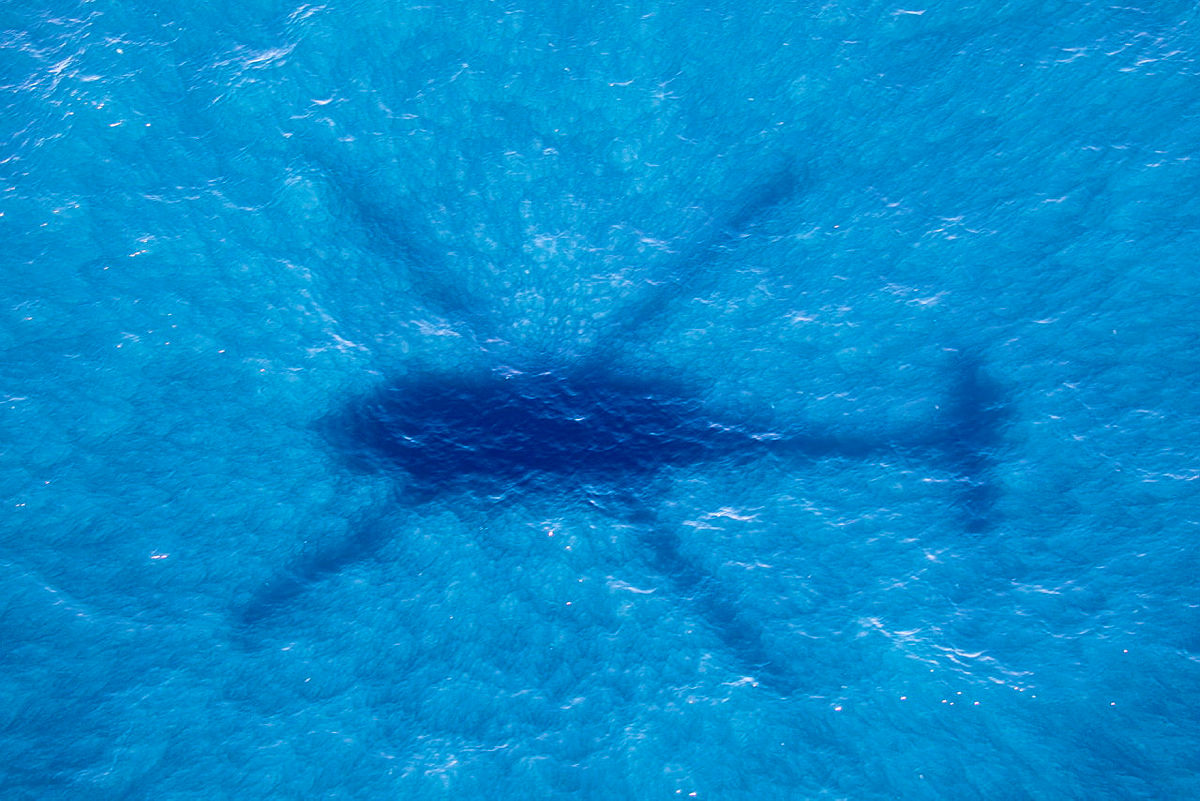

Featured photo: A visit to the USS Ford, October 9, 2020.